La venta termina hoyObtén un 30% de descuento en cualquier curso (excepto paquetes)

Termina en --- --- ---

En esta sección, hablaremos sobre todo lo relacionado con el tuning . Noticias, productos, problemas y resultados.

Hey guys, working on my custom intake manifold design and have a question about injector placement.

The Setup:

V6 twin-turbo,ID1700x injectors (all six identical)Custom fuel rail with individual runners to each injectorThe Question:

Due to manifold geometry my injectors won't all be at the same height. Specifically:

Bank 1 (cylinders 1, 3, 5): Injectors mounted HIGH - spraying into plenum chamberBank 2 (cylinders 2, 4, 6): Injectors mounted ~15mm LOWER - also spraying into plenum chamberAll six injectors are still in the open plenum space (above the runner entrances), just at different heights. They all have clear spray paths with no wall contact.

Will this 15mm height difference cause AFR imbalance between the banks?

I'm concerned that:

Different spray distances to the intake valvesDifferent time in turbulent airflowCould result in Bank 1 running different AFR than Bank 2Additional info:

All injectors feed from the same fuel rail (balanced pressure)Both plenums connected via balance bar (equal boost)All injectors spraying DOWN into open plenum space (high turbulence, good atomization)Height variation is about 20mm (less than 1 inch)What do you think?

Will this require individual bank tuning, or is 15 mm variation small enough that the ECU can handle both banks with the same fuel map?

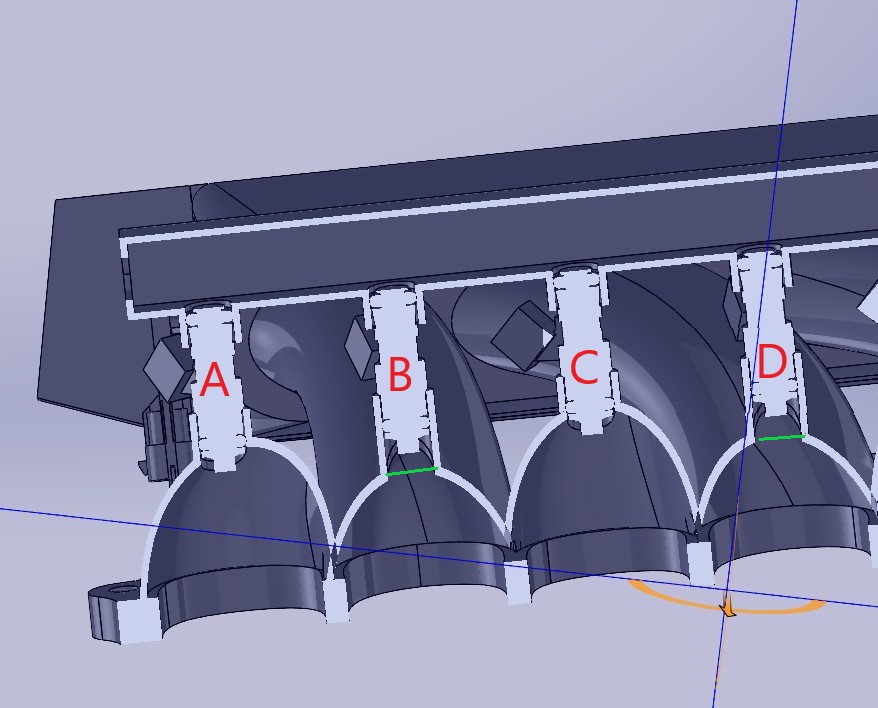

In this example injectors B and D will be lowered to the green lines so that their spray patter is directly in the air flow path

Thanks for any insight!

I doubt anyone will have experience with your design and how it would behave. You will just have to build it and try. Knowing you might have bank variations, it would be wise to select an ECU that can do bank or individual cylinder compensations. You certainly are going to want to run at least one lambda sensor for each bank. If I were verifying a manifold design, I would have one per cylinder for best understanding of the flow variations.

I have to ask, is there a reason you didn't make two fuel rails (one for each bank)? Or consider a common rail that had two different output angles for the injector ports?

Where are your throttles located relative to the manifold shown?

David,

Thanks for your response on this. I will def have bank to bank AFR and can compensate if needed. I am playing around with two rails...or one with different angles...currently waiting on my 3D printer to show up so I can see how this all fits in the real world. Throttle bodies are even spaced on the right and left.

If I understand you correctly, you will be using 2 throttles located upstream of the injectors, and not 6 individual throttles below the injectors.