Walk into any modern motorsport workshop and you'll find 3D printed parts everywhere - from custom ducting and sensor housings to intake manifolds and even suspension components. But here's what separates successful projects from failed prints: knowing which material to use for which application. PLA might be perfect for your mockup, but it'll turn into a paperweight in the engine bay. Nylon could be ideal for that bracket, but only if you're using the right printing technology. Understanding the relationship between materials and manufacturing methods is your ticket from hobbyist to serious builder.

Understanding the different materials available for 3D printing is essential for anyone looking to get started with additive manufacturing. Each printing technology uses specific materials with unique properties, and choosing the right combination can make the difference between a successful part and a failed print. Whether you're prototyping automotive components or creating functional end-use parts, knowing which materials work with which technology is the first step.

In this comprehensive guide, we'll cover the materials used in the four main types of 3D printing: FDM (Fused Deposition Modeling), SLA (Stereolithography), SLS (Selective Laser Sintering), and SLM (Selective Laser Melting). We'll explore the properties of each material, what makes them suitable for different applications, and most importantly, which automotive and motorsport projects they're best suited for.

In this article: FDM/FFF Materials | SLA/MSLA/DLP Materials | SLS/MJF/Binder Jetting Materials | SLM/DMLS/EBM Materials | Choosing the Right Material

FDM/FFF Materials

Fused Deposition Modeling (FDM), also called Fused Filament Fabrication (FFF), is the most common and accessible form of 3D printing. The material used is almost always a thermoplastic polymer that can be melted and re-cured, as opposed to thermosets which can't be remolded or recycled in the same way. While thermoplastics are by far the most common, it's worth noting that using metals with FDM is possible, although metal additive manufacturing is usually done with SLM technology.

The thermoplastic material typically comes in filament form wound onto a spool, although there are alternative forms like pellets which are more commonly used for larger scale industrial printers. The range of materials that can be 3D printed is likely the biggest factor determining the properties and therefore the uses of the finished parts.

Basic Materials

PLA (Polylactic Acid) is widely regarded as the easiest material to 3D print because it's so forgiving with less than ideal print settings, making it simple to get good results. It requires relatively low nozzle and bed temperatures and can be printed at high speed, all while being really cheap. If the most basic printers can only print one material, it'll most likely be PLA. The downside though is that while PLA is reasonably strong and stiff for its low price, it also lacks toughness, or in other words, it is brittle. It also has poor heat resistance. For these reasons, it's not often used in final parts that'll be subject to mechanical and thermal stresses, and it's more likely used for prototypes or parts with less demanding uses. There are developments like PLA+, Hyper PLA, or Tough PLA which provide improved mechanical properties like toughness and also allow for faster print speeds.

ABS (Acrylonitrile Butadiene Styrene) requires significantly more temperature to print and has a reputation for being more of a headache to work with than PLA. While ABS isn't quite as strong and stiff as PLA, it is tougher, holding up better to impact, and also heat. When you require more durability from your part than PLA can provide, but not specifically more strength or stiffness, you'll usually turn to ABS.

ASA (Acrylonitrile Styrene Acrylate) is very similar to ABS, not just in their chemistry but also in their mechanical performance. Compared to ABS, ASA is more expensive and generally less forgiving to print, although with slightly better mechanical properties. The main advantage is a good bump up in heat, chemical, and weather resistance, so if you're printing a part that'll be exposed to the elements, then ASA is a good choice.

PETG (Polyethylene Terephthalate Glycol) is a similar performing material again, just falling short of PLA on the strength and stiffness, as well as ease of printing. It presents similar properties to ABS while being another step tougher and also more resistant to chemicals. One of the key advantages of PETG is how it can be used to print waterproof parts. If you're making an enclosure or something that could be exposed to water, perhaps on the exterior of a vehicle or in the engine bay, and you want the contents to stay dry, then PETG could be a good option.

Engineering Thermoplastics

TPE/TPU/TPR (Thermoplastic Elastomers) are one of the only groups of 3D printable materials that could be described as flexible and, as you'd guess, elastic or stretchable. TPE (thermoplastic elastomer), TPU (thermoplastic polyurethane), and TPR (thermoplastic rubber) fall into the same category. This is a little bit confusing since thermoplastic polyurethane and rubber are technically elastomers. However, some suppliers will still market TPE, TPU, and TPR as three separate products. TPU filaments are more durable and dense, as well as being stiffer, stronger, and tougher. TPE or TPR will usually be lighter and more flexible but not as hard wearing. The first three letters are also usually followed by something like 90A or 98A, which describes the shore hardness. This is a measure of the resistance of the surface to deformation, and that's not to be confused with stiffness. Simply put, a lower number here is softer, and a higher number is harder. These types of filaments are great for parts that need to flex, but also for shock absorption and vibration dampening.

Nylon (PA or Polyamide) can produce a very strong and tough part with impact resistance at relatively low cost. Most notably though, nylon has extremely good heat and abrasion resistance, so it'll usually hold up in abusive environments like the engine bay, within reason of course. There are many different grades of nylon like PA or nylon 6, 66, 11, 12, and 46, all with slightly different properties. For example, nylon 6 is strong and tough at a good price point, whereas nylon 66 has better mechanical properties and heat resistance but at a higher price point. Nylon 12 is known for its flexibility. Even though each grade has the same foundational properties, you can choose between different grades for different applications. You'll most likely see nylon 6 filament on the market due to its price point. It's important to note that FDM 3D printing nylon is not the same as SLS or MJF nylon, which we'll discuss later. If you see 3D printed nylon advertised somewhere, make sure you understand what process it's been produced with, as the results can be significantly different.

PC (Polycarbonate) provides a good step up from the basic materials in strength, stiffness, and heat resistance. It can also be translucent, so it's often used for its optical properties, like plastic covers for components with lights.

High Performance Thermoplastics

This group of materials is commonly referred to as high performance thermoplastics in the 3D printing industry. As you'd expect, there's no free lunch here, and these materials are usually more expensive to purchase and also require more from the printer as well. Some of these materials aren't printable with most consumer grade machines. For FDM 3D printing, this group is dominated by the PAEK family of materials. This includes PEEK, PEKK, PPSU, and PEI, which is commonly called by its brand name Ultem. These materials boast incredible strength for their weight with extremely high heat and chemical resistance, among other impressive properties, justifying their usage across a wide range of different industries. The heat resistance allows you to use these for engine supporting components like intakes, even in high performance and race use. The downside of this heat resistance is the high nozzle temperature required to print the material, which is over 300 degrees Celsius. This puts them out of range for most printers in the consumer market. Even if you can't personally print these materials yourself, it's still worth knowing about them as many 3D printing services are offering them.

Composite Materials

Fiber Reinforced Polymers (FRP) are composite materials made up of two or more constituent materials that usually have dissimilar properties. The intention is to create a material that combines the positive attributes of each material, finding a middle ground and achieving the best of both worlds. There are many different combinations of thermoplastics reinforced with glass or carbon fiber, like PLA-CF, PETG-CF, or PA-6-CF to name a few. The primary intention is to increase the stiffness of the material, and you'll often see a slight bump up in strength as well as an increase in heat resistance in some cases. It's worth noting that this can sometimes also make the material more brittle.

The downside, apart from the expense, is that glass or carbon fiber reinforced filaments are extremely abrasive, meaning they can wear out the components of the printer very quickly. To print them, you need to make sure that components like the nozzle and extruder are up to the task before you risk any damage. What's critical to understand though is the form of reinforcement. Ideally, the reinforcement will consist of short-chopped fibers which are aligned with the filament direction during manufacturing. This way, they will help increase the mechanical properties. Different grades are available, with consumer grades being more basic and cheap with typically shorter and thinner reinforcement fibers. Industrial grade will usually have thicker fibers, and aerospace grade will usually have longer, thinner fibers which lead to lighter but stronger and stiffer parts. These are accompanied by increasing price points, and you'll usually only see aerospace grade carbon fibers used in the higher performance materials like PAEK.

Milled carbon fiber is the alternative option, but you need to be wary. This is essentially carbon fiber powder, and it often doesn't increase the mechanical properties of the material, and it's actually more likely to hurt the strength and stiffness significantly. In some cases, these are just used so the supplier can market the material as carbon fiber. But they do make the appearance of the part nice and smooth with a matte finish, and this shouldn't be ignored.

Automotive and Motorsport Applications for FDM Materials

PLA is best suited for non-functional prototypes, aesthetic mockups, or low-demand interior trim pieces where heat and mechanical stress aren't concerns. ABS and ASA are better choices for functional parts like ducting, interior panels, or any exterior components that need weather resistance, making ASA ideal for body panels or exterior mounting brackets. PETG excels in applications requiring chemical resistance or waterproofing, such as fluid reservoirs, engine bay enclosures, or electrical component housings. TPU materials are perfect for vibration dampening mounts, flexible boots and gaskets, or handle grips where a softer touch surface is beneficial. Nylon stands out for its heat and abrasion resistance, making it suitable for intake manifolds, engine bay brackets, cable management components, and linkages. Polycarbonate is ideal for light covers, lens components, or any translucent parts. High performance PAEK materials are best reserved for extreme applications like turbo inlet piping, valve covers, or high-temperature sensor housings where both heat resistance and strength are critical. Carbon fiber reinforced composites are excellent for aerodynamic components, structural brackets, or any part where increased stiffness justifies the cost, though they're less suitable for applications requiring layer-direction tensile strength.

SLA/MSLA/DLP Materials

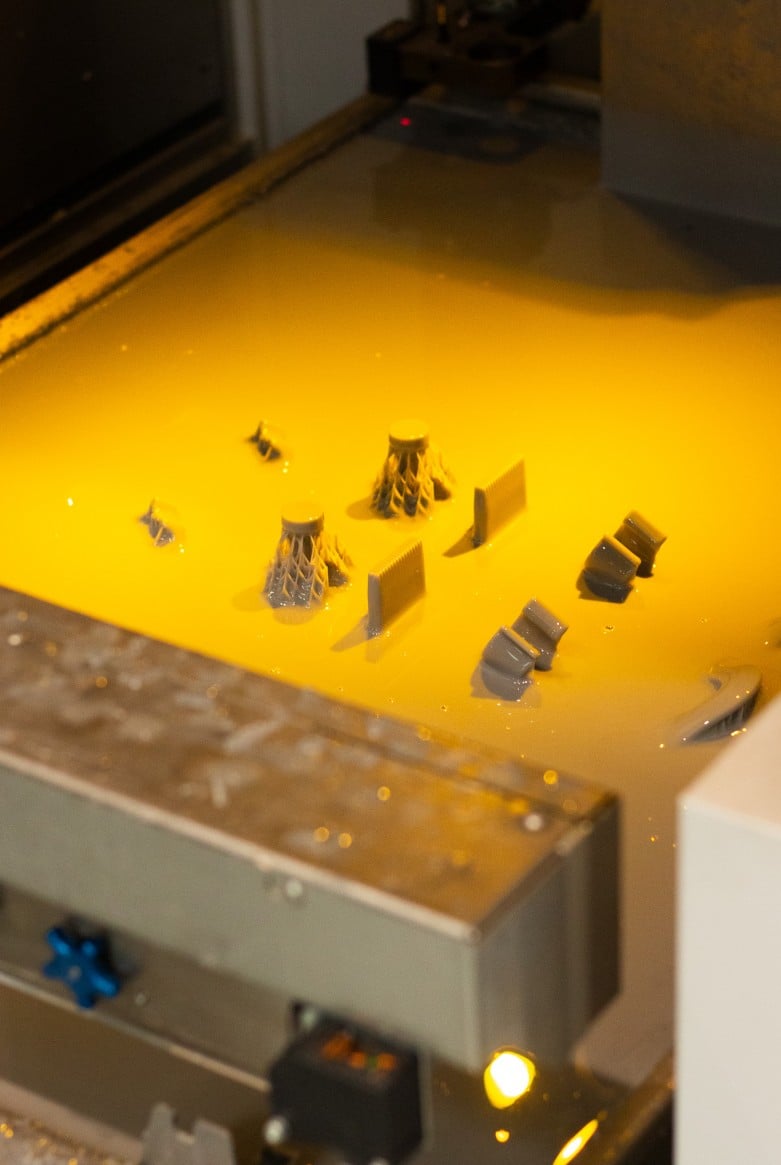

Stereolithography (SLA) 3D printing uses liquid resin that cures when exposed to light. At first glance, the options for different materials will seem extremely limited compared to the never-ending list of filaments for FDM. But past the basic and generic offerings, there's a relatively wide range of resins available for all different applications. Epoxies, acrylics, polyurethanes, silicons, and ceramics are all common options for the base components of the resins. While each of these provide different properties, this isn't usually the most effective means of understanding what type of resin is suitable for each application.

Thankfully, the properties of each resin are much easier to understand simply by their names, especially compared to the confusing three-letter abbreviations for the chemical compounds of filaments for FDM. Most suppliers will market their resins under names like Standard Resin, Rapid or High Speed Resin, Water Washable Resin, Tough Resin, Translucent Resin, or Transparent Resin. All the options can be divided into a few categories: General Purpose, Engineering, Dental or Medical, and Jewelry. We're primarily interested in the General Purpose and Engineering categories.

General Purpose Resins

Standard Resin is the most commonly used resin that you'll almost always start your SLA 3D printing journey with. It's a simple and relatively cheap option with no real standout properties, but it's well-rounded and makes use of all the typical benefits of resin printing, offering a good surface finish and level of detail. The strength, stiffness, and temperature resistance are all fairly good but not particularly special in any way when compared to other options. Standard Resin is the go-to for most low-demand parts and prototypes. The HDT (heat deflection temperature) is a measure of a polymer's resistance to deflection under a specific load at an elevated temperature. For example, the HDT of a standard resin at a load of 0.45 megapascals is about 48 to 70 degrees Celsius. Although a certain part might not always be subject to load, so it could probably handle much higher temperature than this in that case, the HDT will usually be the specific value from the material supplier, and it's fair to say that a higher HDT generally means higher heat resistance.

Water Washable Resins are very much the same as standard resins but can be cleaned only with water after printing, rather than standard resins which typically require isopropyl alcohol to dissolve and remove excess uncured resin. These are a recent innovation, and the only real downside is the higher price point, which is partially justified by reduced isopropyl alcohol usage. Either standard or water washable resins are available in a range of different surface finishes like gloss or matte, as well as colors and transparent or translucent options for aesthetic or optical purposes. For the most part, these color and transparency options have no real impact on any mechanical properties.

High Detail or Precision Resins usually result in prints with similar mechanical properties to standard resins. However, the resins are specifically designed to have low shrinkage during printing. This leads to more accurate prints, ideal where geometric accuracy is critical or in parts with high level of detail. As you'd imagine though, this typically comes with a slight increase in cost.

Rapid Resins are suitable when you're prioritizing efficiency and print speed over quality and surface finish. That's not to say the results are bad, maybe just not quite as good as normal. With that said, if you're using these resins, quality probably isn't your priority anyway.

Engineering Resins

Flexible Resins replicate the flexibility of rubber or TPU like we discussed with FDM filaments. These are still relatively strong but not stiff, and allow for a good amount of deflection while returning to their original form, although that happens relatively slowly. This makes them ideal for shock absorption parts or things like handle grips where you want a softer touch surface that's still firm enough for good control.

Elastic Resins are similar but much softer and faster to spring back to their original shape, although they don't have the same strength.

Silicon Resins are much the same as flexible and elastic resins, being relatively soft and pliable but also quite durable with good heat resistance. These can be used to recreate parts like steering rack or CV boots, or even gaskets, o-rings, and seals.

Rigid Resins are usually glass filled or reinforced with glass fibers. This makes them extremely stiff, which is great for equipment that you don't want flexing, like aero parts. Rigid resins also offer high HDT values along with the stiffness, so they can handle hotter applications as well.

Tough Resins and Polyurethanes split the difference. These are still strong and stiff like standard resins but also allow for much more elongation, meaning they can stretch and bend much more without failing, making them great for rugged parts that can be subject to impact. These resins are often marketed as ABS-like or nylon-like resins due to their increased impact resistance. If you're making any kind of tooling to produce other parts like jigs and fixtures, then these are often the go-to for long lasting parts.

Durable Resins are similar but usually a lot less stiff and considerably more ductile, allowing for even more elongation.

High Temperature Resins are typically the go-to for parts in the engine bay and can be capable of handling temperatures over 200 degrees Celsius, which is about 400 degrees Fahrenheit.

Ceramic Resins offer properties like flame retardancy, conductivity, and exceptional heat resistance and are suitable for specific applications.

Automotive and Motorsport Applications for SLA Materials

Standard and water washable resins are best for prototyping, aesthetic mockups, and low-stress interior components where surface finish and detail are more important than mechanical performance. Precision resins excel in applications requiring tight tolerances like sensor housings, mounting brackets with precise fitment, or any component where dimensional accuracy is critical. Rapid resins are ideal for iterative prototyping where speed matters more than final quality. Flexible and elastic resins work well for boots, dust covers, vibration dampening mounts, or soft-touch control surfaces. Silicon resins are excellent for creating custom gaskets, seals, or boots that need heat resistance. Rigid resins are best suited for aerodynamic components like splitters or diffusers where stiffness prevents unwanted flexing, or for intake manifolds and ducting that need to maintain their shape under heat. Tough and durable resins are perfect for jigs, fixtures, mounting brackets subject to impact, or functional end-use parts in the cabin or suspension that need impact resistance. High temperature resins are the choice for engine bay components, turbo system parts, or any application exposed to sustained high temperatures where standard resins would soften or fail.

SLS/MJF/Binder Jetting Materials

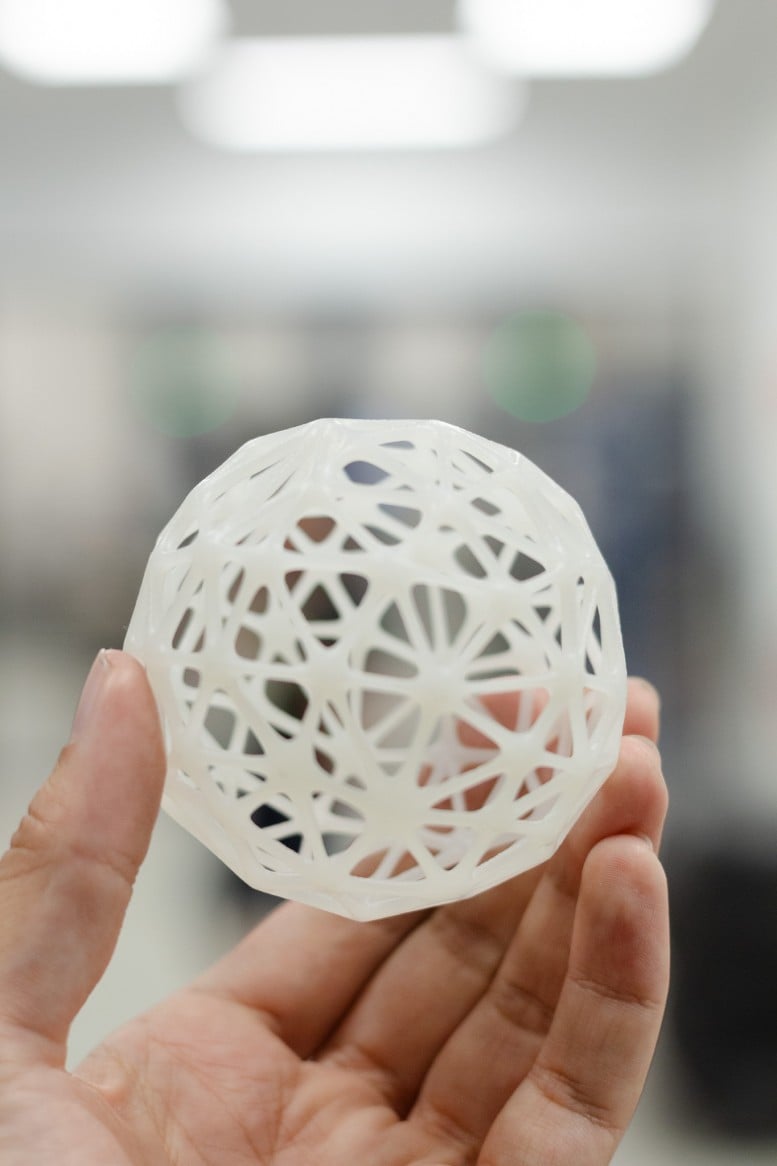

Selective Laser Sintering (SLS) and Multi Jet Fusion (MJF) use thermoplastic powder materials. While these are somewhat limited compared to FDM, some projects justify the use of SLS primarily for the design flexibility and the fact that parts are more isotropic and significantly stronger than FDM parts. SLS parts also don't require support structures since the unfused powder acts as natural support, allowing for more complex geometries.

Nylon Materials

Nylon (PA or Polyamide) is really the go-to for SLS, and it's also used almost exclusively for MJF printing. Nylon is considered an engineering thermoplastic and can be used to print very strong and tough parts with impact resistance at relatively low cost. Most notably though, nylon has extremely good heat and abrasion resistance, so it'll usually hold up in abusive environments like the engine bay, within reason of course. There are many different grades of nylon and they all have different properties, but for SLS and MJF, nylon 11 and 12 are used most often.

Nylon 12 is the most well-rounded and usable of the two for most use cases. It's very stiff and extremely long lasting due to wear resistance. It can handle relatively high temperatures, but it's also much better at extremely low temperatures if you're making parts for a street car and you live in cold climates.

Nylon 11 also has great strength, heat resistance, and chemical resistance to fuels, oils, and grease that you use on cars. Nylon 11 provides better flexibility though, being much more ductile. This makes it perfect for applications where the flexibility has a function, like snap fit clips or live hinges, but also parts that need to handle impacts.

Glass or Carbon Reinforced Nylon is common for SLS printing. This is usually done to increase stiffness and also heat resistance, allowing for functional end-use parts for more demanding applications.

Other SLS Materials

TPU (Thermoplastic Polyurethane) powder is an elastomer. For SLS, this is typically 90A hardness, meaning the surface is relatively firm and generally can't be deformed by hand. This shouldn't be confused with stiffness, as the structure of the part will be very flexible and elastic while still being resilient and wearing well. SLS printed TPU is ideal for parts that are handled often, like levers or controls, but also for shock absorption or vibration dampening.

Polypropylene is used extensively in injection molded parts and it's just as useful in additive manufacturing, producing parts that are very lightweight with good heat and chemical resistance. This resistance paired with its watertight nature mean that it's ideal for holding parts together and holding and transporting fluids in reservoirs, pipes, or ducts. It's not as stiff as nylon or as flexible as TPU, but it's still relatively ductile, strong, and impact resistant, so it's often used for body panels.

PEEK is a more recent addition to SLS materials. It provides extremely good heat resistance without compromising structural integrity, making it very useful for demanding motorsport applications like in race car engine bays.

Automotive and Motorsport Applications for SLS/MJF Materials

Nylon 12 is the workhorse material for functional end-use parts requiring durability and stiffness. It's excellent for intake manifolds, ducting, cable management systems, electrical housings, and structural brackets. Its wear resistance makes it ideal for sliding components or parts subject to abrasion. Glass or carbon reinforced nylon takes this further, suitable for high-stress structural components, suspension linkages, or aerodynamic elements where additional stiffness justifies the cost increase. Nylon 11's flexibility makes it perfect for snap-fit assemblies, living hinges, clips and fasteners, or impact-prone components like undertray mounts. TPU excels in applications requiring flexibility like bellows, flexible boots, soft-touch controls, or heavy vibration dampening. Polypropylene is best for fluid reservoirs, coolant expansion tanks, ducting for air or fluids, lightweight body panels, or any component requiring chemical resistance to automotive fluids. PEEK is reserved for extreme applications like turbocharger components, high-temperature sensor housings, or any engine bay part requiring both structural integrity and heat resistance beyond what standard nylon can handle.

SLM/DMLS/EBM Materials

Selective Laser Melting (SLM), Direct Metal Laser Sintering (DMLS), and Electron Beam Melting (EBM) are forms of metal powder bed fusion. These technologies open the door to much more suitable properties for demanding motorsport applications. Most of these materials are alloys. For clarity, an alloy is a material composed of two or more elements, one of which must be metallic. The term alloy is commonly misused as a synonym for aluminum. Clearly, pure aluminum isn't an alloy, but there are aluminum alloys, and these are predominantly aluminum, usually over 90 percent, with small amounts of alloying materials.

Aluminum Alloys

Aluminum Alloys are well suited to performance applications thanks to their high strength to weight ratio and corrosion resistance. They're also relatively cheap and easy to work with as far as metals go. The aluminum alloys used in additive manufacturing are much like those used in billet parts, with major alloying elements of magnesium for extra strength and silicon which lowers the melting temperature, helping with manufacturing processes like SLM where you melt the material.

AlSi10Mg has approximately 90 percent aluminum, 9 percent silicon, and 1 percent magnesium, and is a solid all-rounder for good mechanical and thermal properties, specifically the strength to weight ratio and stiffness. It's ideal for structural components like housings, brackets, and linkages, as well as ducting, intake manifolds, and other plumbing.

AlSi7Mg is an alternative that offers advantages in thermal conductivity, making it suitable for heat exchanger components like intercoolers.

6000 Grade Aluminum offers improved strength, ductility, and surface finish, while 7000 grade has even higher mechanical properties and is commonly used for aircraft parts.

Stainless Steel

Stainless Steel is known for its amazing strength, durability, and corrosion resistance, although not being as light as aluminum. There are a few different grades of stainless steel available for 3D printing.

316L is commonly called marine grade stainless steel thanks to its excellent corrosion resistance. This is suitable for anything exposed to the elements on the exterior of the vehicle.

630 Grade (17-4 PH) is more commonly used in additive manufacturing for more strength and mechanically demanding applications. 15-5 PH is another modification with slightly better stability at higher temperatures. Either are great options for applications where the strength of aluminum isn't sufficient, although this comes with a weight penalty. Good examples would be engine components or turbo manifolds.

Titanium Alloys

Titanium has a better strength to weight ratio than stainless steel and even aluminum. For the same strength, a titanium part will typically weigh around 40 percent of the equivalent stainless part. It has better corrosion and chemical resistance than stainless, so the parts remain in good condition for longer. However, titanium isn't nearly as durable as stainless. It's much softer and more susceptible to dents and wear from abrasive conditions.

The different grades of titanium are generally named grade 1, 2, 3, and so on, going all the way up to grade 38. Grade 1 is the softest and most ductile and is used in motorsport, but not anywhere near as common as Grade 5 (Ti-6Al-4V), also known as titanium 64 or 6-4, which boasts considerably better mechanical properties.

What's important to understand is the use of titanium in high-temperature applications like exhausts. Titanium has low thermal conductivity and high melting temperature, which makes it appealing for high-temperature use. However, it actually breaks down at a much lower temperature than stainless. After long amounts of time exposed to elevated temperature, it becomes very brittle and starts to crack or fracture. While it might be suitable for applications like exhausts on higher-end motorsport builds where the weight saving justifies the shorter service life, it's not ideal for street cars or more budget-restricted race cars. That's not to say it can't be used with success though, especially when temperatures aren't as severe.

Grade 23 (Ti-6Al-4V ELI) is similar to grade 5, although with extra-low interstitial content. This means the oxygen and iron content are reduced, improving ductility and fracture toughness, helping to reduce the brittleness issues. Titanium is still used in valve trains and other engine components like connecting rods, although most commonly in naturally aspirated applications where temperatures are generally lower. Anything past this is more suited to structural and suspension applications, with 3D printed titanium even seeing use in wheels. Its extra expense is generally only justified by its use on larger parts where weight savings are more significant, although the savings for many smaller components like fasteners can add up when you're trying to shave every last gram.

Nickel-Based Superalloys

Inconel is a nickel-based superalloy. A superalloy is able to operate at a very high fraction of its melting temperature while maintaining a high fraction of its properties. These include high mechanical strength as well as excellent thermal and corrosion resistance. Inconel is ideal for extremely high-temperature applications around the engine like exhaust manifolds, turbo wheels, exhaust valves, or even battery contactors on EVs.

The two most common grades of Inconel for automotive use are 625 and 718. Simply put, they both have great mechanical properties and thermal resistance, but 625 has better corrosion resistance and 718 is stronger. 718 would be the choice for an exhaust manifold, whereas 625 would be more suited to plumbing that conveys chemicals or a heat exchanger like an oil cooler. With that said, realistically either could be used with success in most applications.

Automotive and Motorsport Applications for Metal 3D Printing Materials

Aluminum alloys are the go-to for weight-critical applications requiring good strength. AlSi10Mg is excellent for intake manifolds, turbo piping, structural housings and brackets, suspension linkages, fluid manifolds, and ducting where weight savings over steel are valuable. AlSi7Mg is better suited for heat exchangers like intercoolers or oil coolers where thermal conductivity is important. 6000 and 7000 grade aluminum offer higher performance for stressed structural components, making them ideal for suspension uprights or highly loaded brackets where the performance justifies the cost. Stainless steel 316L is best for exhaust components, exterior brackets exposed to weather and road salt, or any application requiring maximum corrosion resistance. 17-4 PH and 15-5 PH stainless excel in high-stress applications like turbo manifolds, exhaust hangers subject to high loads and vibration, engine mounts, or any component where aluminum strength is insufficient but weight isn't as critical as durability. Titanium grades 1 and 5 are suited for connecting rods in naturally aspirated engines, valve train components, suspension components where weight reduction is critical, fasteners throughout the vehicle, and wheel components. However, titanium should generally be avoided for turbo exhaust applications due to brittleness at sustained high temperatures unless using Grade 23 with proper heat treatment. Inconel is the premium choice for turbocharger manifolds and housings, exhaust valves, turbine wheels, or any component requiring sustained operation above 800 degrees Celsius. While expensive, Inconel is often the only material capable of surviving extreme heat applications, making it worth the investment for top-tier builds where reliability under extreme conditions is non-negotiable.

Choosing the Right Material for Your Project

With so many materials available across different 3D printing technologies, choosing the right one comes down to understanding your specific requirements. Start by considering the mechanical demands: does the part need to be strong, stiff, flexible, or impact resistant? Then consider the environmental factors like temperature exposure, chemical resistance, or UV degradation from sunlight. Don't forget about the practical aspects either, such as your budget, the equipment you have access to, and your skill level with different technologies.

For beginners just getting started, FDM with PLA is the most forgiving and accessible option for learning the basics. As you gain experience and your projects become more demanding, you can move to materials like ABS, nylon, or even start exploring resin printing with SLA for better surface finish and detail. For functional parts that need to withstand real mechanical loads, SLS nylon or metal printing might be necessary, though these often require using manufacturing services rather than printing at home.

Remember that everything discussed in this guide represents generalizations, and there is plenty of variation in material properties between different suppliers. PLA from one supplier will be similar but not the same as from another supplier. The price, quality, consistency, and properties will all vary to some degree. It's also worth noting that formulations can vary between different manufacturers and result in significant differences in properties even with the same type of material. With this in mind, it's worth discussing your specific requirements with the material manufacturer if you have any doubt.

The best way to truly understand these materials is with hands-on experience. Start with simpler materials and projects, learn what works and what doesn't, and gradually work your way up to more advanced materials as your skills and requirements grow.

Conclusion

Understanding the full range of materials available for 3D printing opens up incredible possibilities for automotive and motorsport projects. From simple PLA prototypes to high-temperature Inconel exhaust components, each material and technology has its place in the workshop. The key is matching the material properties to your specific application requirements, considering factors like strength, heat resistance, flexibility, weight, and of course, budget.

While this guide provides a comprehensive overview of materials across FDM, SLA, SLS, and metal 3D printing technologies, there's no substitute for practical experience and the best use of your time to get great experience is with the Practical 3D Printing course.

Also a huge thank you to fi innovations for letting us take and use many images from their workshop along with sharing their knowledge on some of the materails we use less commonly ourselves but wanted to include information on for readers like yourself.