They say the devil is in the detail, and when it comes to setting up an EFI system this statement couldn’t be more true. It’s often some of the more basic elements that are overlooked, and these elements can cause wasted time, wasted money and possibly even a damaged engine. Even if you’re not planning to tune your own engine, I know a many enthusiasts will get their car up and running for the first time before taking it to the dyno shop for tuning. In this case, it pays to know how to cover some of the basic configuration jobs such as setting the base ignition timing and fuel pressure. In our last article we covered the ignition timing, so this time we’re looking at the fuel pressure.

In this article: Finding the correct fuel pressure | Setting your fuel pressure

Fuel pressure isn’t particularly complex – it’s simply the pressure in the fuel system being generated by the flow from the fuel pump. The fuel pressure does have a dramatic effect on how the injectors will operate though, and in particular how much fuel they will deliver. As far as the fuel injector is concerned, it’s actually not just the fuel pressure that’s important but the difference between the fuel pressure in the fuel rail and the air pressure in the intake manifold. This is called the differential fuel pressure. The differential fuel pressure is what will determine how much fuel an injector provides for a given pulse width, as well as some of the more subtle aspects of the injector’s operation. Let’s look at why this is the case…

Let’s say for example we have a turbocharged engine and we’re driving along with the boost pressure reading 0psi. At the same time, let’s assume the fuel pressure in the fuel rail is set at 45psi. The differential pressure is simply the difference between the fuel pressure and the manifold pressure – in this case 45psi. At this point, when the injector opens there is more pressure in the fuel rail than the intake manifold so fuel will flow. What happens though if our fuel pressure stays fixed at 45psi and we wound the boost all the way up to 45psi? Well, if our fuel pressure has remained at 45psi, the differential pressure is now zero and when the injector opens, no fuel will flow since the air pressure and the fuel pressure are equal.

What you can learn from this is that the amount of fuel the injector will deliver is relative to the differential pressure across the injector. The higher the differential pressure, the more fuel the injector can flow, and as the differential pressure drops so does the fuel flow. This is important to consider if you’re adding a turbo to a late-model engine with a return-less fuel system where the fuel pressure remains constant. As you start adding boost pressure to the engine, the differential fuel pressure drops, reducing the available flow from your injectors.

Finding the correct fuel pressure

Since the fuel pressure is so critical to the injector’s performance, it makes sense that setting the fuel pressure is one of the first jobs we need to do before tuning. If your fuel system is still 100 per cent standard then there shouldn’t be much work for you to do as the fuel pressure won’t be adjustable. Even if this is the case though it’s still important to know what the fuel pressure is. This can help you diagnose problems if the fuel pump can’t keep up, and when you’re setting up an ECU prior to tuning you’re going to need to know what the fuel pressure is so you can enter the right data for your injectors. If you have an adjustable fuel pressure regulator then you have the potential to set and adjust the fuel pressure you’re running, and this leads to a few more questions like ‘what should my fuel pressure be?’

The correct fuel pressure is really going to depend on what you’re using the engine for. What’s right for an everyday road car won’t be suitable for a drag engine running 60psi boost for example. A good guideline is to look at what the OE manufacturers do and here we will usually find that in a return-less fuel system that uses a constant pressure, the fuel pressure will be 58psi or 4bar. If your fuel system uses a manifold pressure referenced fuel pressure regulator then the fuel pressure is typically 43.5psi or 3bar. This is a good starting point but these numbers aren’t set in stone.

Since the amount of fuel an injector can supply is largely dependent on the fuel pressure, this is a consideration when you’re setting the fuel pressure. Particularly if your injectors are getting near their duty cycle limit and you just need a little extra fuel, increasing the fuel pressure can give you the extra headroom you need. You do need to be careful how far you go when increasing the fuel pressure though, as the higher the fuel pressure the harder the fuel pump needs to work and often we can find that the fuel pump can’t keep up. This means you’re back in the same position of not being able to supply enough fuel to the engine. You also need to be mindful that you can’t just go increasing the fuel pressure indefinitely. As you increase the fuel pressure it becomes harder and harder for the injector to open, and at some point the injector simply stops flowing fuel.

Setting your fuel pressure

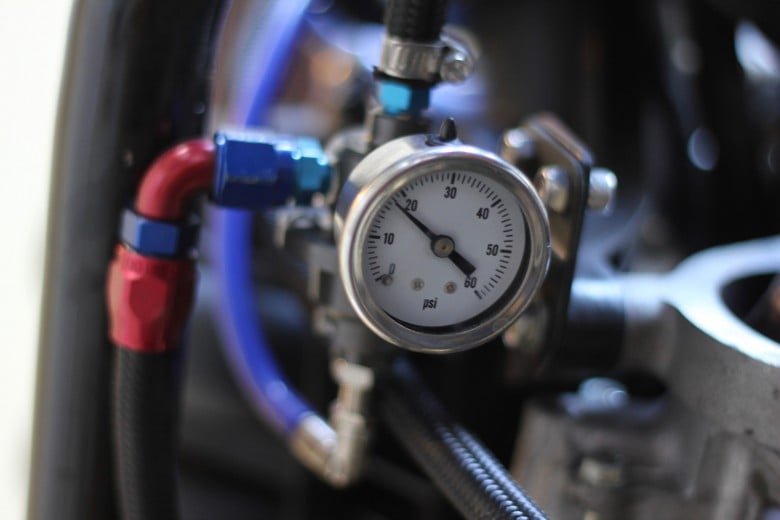

Setting the fuel pressure is pretty simple, yet there are still a couple of places you can trip up. The first thing when setting or checking the fuel pressure is to make sure you do it with the engine running. If you turn the ignition key to the run position without starting the engine, the fuel pump will run for a few seconds to prime the fuel system, and on the face of it you’d think you could check the fuel pressure during this time. The problem with doing this is that the fuel pump is electric and the amount of fuel the pump can supply is dependent on the voltage it receives. When the engine isn’t running the alternator isn’t charging the battery and the voltage reaching the pump will be lower than what it will see when the car is running. This can give a fuel pressure reading thats a little lower than you will see with the engine idling.

The second point if you’re using a fuel pressure regulator that has a vacuum hose running to the intake manifold is that you need to set the fuel pressure with this hose disconnected. The fuel pressure regulator’s job is to maintain a constant differential fuel pressure across the injector and this means that at idle when there is a vacuum in the intake manifold, the regulator will reduce the fuel pressure. If you adjust your fuel pressure with the vacuum hose connected, the resulting differential fuel pressure is actually going to be higher than you expect.

Even once you’ve got the base fuel pressure set it’s still helpful if you can monitor the pressure while the engine is being tuned. This can prove to be a big help in diagnosing problems with the fuel delivery while the car is on the dyno that can otherwise be time consuming to find. If you’ve got an electronic fuel pressure sensor permanently fitted to the engine and wired to the ECU then you can also employ some engine protection strategies if the fuel pressure drops for any reason.

Lastly, any time you’re working on the fuel system you need to take suitable precautions. It should go without saying, but a fuel leak could be potentially devastating. Always make sure that there is no pressure left in the fuel system before removing any fittings, and always ensure that fittings are correctly tightened and leak free when reassembled. In particular, I find Loctite thread sealant is an easy way to seal the tapered plugs that are used to blank off the pressure ports on aftermarket fuel pressure regulators. It’s also easier to work with than thread tape.

As with many things in the world of modified cars, our options aren’t always completely clear and obvious when it comes to tuning. If you’ve still got questions, ask them on our members only forum and I'll do my best to help you out.

Want to learn more about EFI tuning? Why not start learning to tune with our free course?