Sale ends todayGet 30% off any course (excluding packages)

Ends in --- --- ---

Maybe best place to put on the diesel side of this forum as it’s all diesel.

This is one of the project where we can show some of what the diesel industry is able to produce as on this engine lots of special parts are needed and must say for me it a love & hate it engine with it’s good and bad things. Fact is it’s an old so we need to crank it up with loads of latest generation stuff and production techniques to get max engine performance.

First is what I do not like on this engine.

Fuel system. Lost of internal leaking costing engine power as more fuel needs to be pumped to the hi pressure side of the fuel system. (common rail). More later on during the build how and why.

Things in general we like about this engine.

Low in weight around 900Kg in total. Not bad for a 12.4L Semi truck engine.

Small and compact build. More a bout this later on.

Some of the numbers on performance. Engine power. Fuel system can handle over 1500Hp. Fit a bigger turbo and get more power.

Torque. Close to 6000Nm. Why is this important? Well this engine going to run FIA European truck race championship with a 63mm inlet restriction size limiting the airflow to the engine so massive low end power or Torque will give you a wider RPM range with max engine power.

Small youtube movie on what is coming and what the engine looks like.

[url=http://www.youtube.com/watch?v=KSKp7rI6yR8]www.youtube.com/watch?v=KSKp7rI6yR8

Looks like a cool project. Will follow this as your progress.

D26E6 Truck Race engine Piston and injector explained

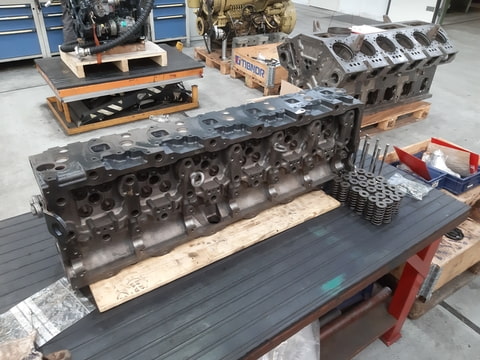

We get the engine striped down to what we call a small block. Rotating assembly engine block liners and connecting rods & pistons still in place so next week will disassemble these as well.

Cylinder head will be cleaned over the weekend to get all the soot out if the intake system as this engine runs EGR and inlet manifold is part of the cylinder head.

Valves are removed from the cylinder head and will be machines to specification. Some small changes to the meeting face of the valve and valve seat will improve heat transfer.

The rest of the cylinder head job is boring as no need to the in/exhaust porting is needed.

The rest of the job is inspect for cracks but we know the head has been replaced before so it should be fine. Must say due to the very hi combustion pressure on these race engines a cylinder head will last about 1,5 years racing and if the head creaks chance is the vale seats will fall out. Last thing is the clearance of the valve guides. Make them to small and the valve will stick. Make it to big and chance is on the exhaust valve is that burned oil will stick to the valve stem and make it stick as well. Get the clearance correct and all will work fine also providing max cooling to the valve as well as the valve stem will transfer heat to the cylinder head by a small layer of oil. Oil dos a loads more than only lubrication.

Oil, top piston ring sealing and cooling the top of the outer piston. What did you say? Did you know that 90% of heat transfer or the outside of the piston top takes place by the top piston ring? Just have a look @ a piston on that part and you notice the material thickness is the most on that part so it dos not only want to expand more but its also harder the transfer heat to the inside of the piston. So if your top piston ring dos not seal very well oil will be pushed down or out of the piston grove creating not only a load of blow down of combustion gasses but reducing piston cooling or heat transfer to the cylinder liner as well. An alloy piston will expand to a point all clearance is gone and it will leave alloy on the liner as well due to overheating and this stuff is very abrasive. A steel piston will expand a lot less but chance is the piston it self will get that hot that the piston pin will expand unable to rotate in the small end of the connection rod and things like friction welding the piston pin to the piston will lake place as it’s steel on steel and later on I will show you how small the services are on a steel piston and what can happen if it all dos not work out.

Engine is now completely striped and all parts are inspected for size and damage and cracks so yes very happy as all is still within factory specifications. Engine block is in the machine shop for some modifications needed to fit some special parts.

https://myalbum.com/photo/k2AEgJJzbRhV/1k0.jpg

https://myalbum.com/photo/b5nmxmGMF3R4/1k0.jpg

We also have an engine test system. You can call it a universal ECU system for diesel engines so we are able to test customers engines after they done there overhaul or repairs so they know all is OK before they sent it out to there customers.

I do not put a lot of effort in connection all sensors. Cam sensor is not needed as I programmed a auto sync on 720 crank or 4 stroke cycle detecting engine acceleration @ start-up.

Load testing a Liebherr D936 commonrail engine

[url=https://www.youtube.com/watch?v=MuLvdRnOtl4]https://www.youtube.com/watch?v=MuLvdRnOtl4

This MAN has a compound turbo set-up. Small turbo for low end performance and the bigger one for mid and hi end power. compound turbo set-up is very basic as they use the wastegate on the smaller turbo to bypass exhaust gasses to the bigger turbo but still all intake air will pass over the smaller turbo so it always remain in operation as on some engine the smaller turbo will be bypassed with some vale system as well.

Also note the air to water after cooler system on this engine and the EGR coolers as well. This D3676 is the bigger 16L brother of the D2676 race engine we build.

Load testing a MAN D3676LA01.D engine

[url=https://www.youtube.com/watch?v=jEIa-KYucuA]https://www.youtube.com/watch?v=jEIa-KYucuA

Also part of my daily work is engine diagnostics. What to make from this one? Engine gets above 60 degrees C coolant temp and starts smoking white out of the exhaust coming out of idle RPM un till getting into some boost. First thing that comes to mind EGR valve open to far? Nope and EGR + cooler already replaced as this things went on for some time now even the dealer diagnostics expert is out of option on what it can be.

So what’s next? Get a diagnostic tool and start looking for strange things on sensor readings.

OK notice that AFR was 16.8 on idle EGR valve closed!? DPF sensor reads only 2Kpa but lines to DPF sensor can be blocked so crawl under this very low city bus undo the pressure lines on the DPF sensor. Nope all are open and not blowing very hard so no backpressure on DPF and so on. OK next step. Take the MAP sensor out, yes blows air out of the hole on the inlet manifold. Looks OK. Next thing look @ the AFR reading getting out of idle soft and hard pressing the accelerator peddle. Go slow up in RPM all is OK. Go hard and AFR jumps below 14.2AFR. Engine has the same compound turbo set-up as the MAN D3676LA01 so some exhaust pressure on low end is normal but should not give massive EGR working on the engine unless the wrong camshaft is fitted. OK here is where you jump back to the engine build manual and if you know camshaft timing and valve open/close diagrams on diesel engine you know what will happen if you have to big numbers on valve chance over duration and exhaust gas pressure will do more than even keeping some exhaust gas in the combustion chamber. Exhaustgas will enter the inlet manifold as well.

So in this case there is a camshaft for internal and external EGR controlled engines.

This makes for some very interesting reading. The diesel piston was also quiet new to me so thanks for sharing.

The Dakar Rally Game is on. Shake down special stage 5e place and best private team only 8 seconds behind Nr1. Ideal for starting day one.

Scania 12.7L Commonrail 1130Hp over 5000Nm

Day 2 of the Dakar Rally is already underway. Have daily contact with the Dakar Speed Rally team. Everything under control, make no mistake much is new about the new Scania or is it now an International. There has been some testing but this is THE rally of rallies so I see it as a test year.

Preserved and still sticking to it, 11th place is good for me, it’s a long rally.

Scania engine technology. Apart from a few minor things, it is actually the same as all race and rally bikes. What is new is the automatic gearbox. This was a point of discussion because many Rally teams drive this set-up with more engine revs and the Scania engine that we build like a torque machine, a lot of pulling power underneath which also saves fuel, etc. and also make this engine a has a higher average power, comment of 1 of the Dakar Speed team members, they can't keep up with us out of corner, the power delivery impresses other teams.

What can I say! Game over for 2021 Dakar Rally. Big crash Dakar Speed Rally Team Scania International Dakar Rally 2021 stage 3

Just shows how fast things can go. Also shows how easy this truck takes the dunes up shifting to 4e gear. They were running around 6e place keeping up with the top 6 easy but yes motorsport can have it’s bad days.

[url=http://www.youtube.com/watch?v=QFNJGWJwZ8w]www.youtube.com/watch?v=QFNJGWJwZ8w

I think we can all agree this. It’s the most epic looking Rally Truck Around. A head turner.

Such a shame. That truck looks awesome.

Flat out on work so not a lot of time to post things. And yes load of new things coming for 2021.

As for the future of commercial transport we hope to start load testing our https://smesh-e-axle.com next week. Please have a look at our website for more information.

Work in progress D26E race engine(s) 2021 spec. As always it’s the combination of man and machine that’s make the difference on overall performance. We can make massive toque and power numbers from our engine but what good will it be if its hard to control. Some things are not for sale or rent you just get them along with our products only and it’s called know how.

While most are still working on the basic things of making power. I concentrate on getting the engine more fuel efficient.

Simple air inlet is restricted an the same for all teams due to FIA race organisation inlet restrictor and most race engines are factory supported so effort is made to max engine performance so where can I gain some power?

Take fuel efficient and swap it round to how can I make more power with same amount of fuel and air? Well last thing remaining is friction and ancillary drive losses like fuel water and oil pump. In total 5 to 10Kw can be found or reduced. Dos not sound like a lot on about 1100Hp but when your customers are racing for a win lap times can vary 0,1sec having pole potion so on that level of performance you need to max out things.

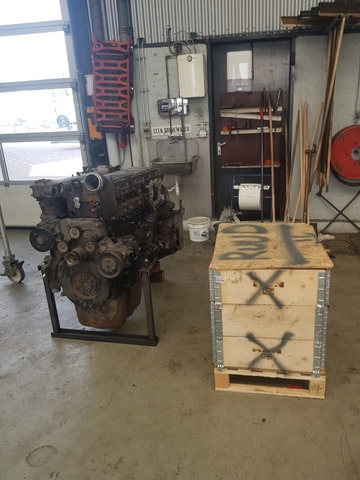

This is how they come in for the next race engine build. Good used engine but most is not used. Engine block, crank, most of the gears fuel and oil filter unit, injectors bodies and some covers are used. The rest goes out as used parts.

Bit of plug and play fun with a CR diesel.

Tractor running one of our Baldur DID1 ECU running a Mercedes OM613 out of a S320 CDI

https://www.aftermarketecushop.com/diesel-ecu-ecm/did1-common-rail-diesel-ecu

Together with Dieselmeken AB we done there ECU set-up for OM648 engine that is the next Gen after the OM613. bigger pump and injectors by Dieselmeken AB and these engines go over 1000Nm 6 to 700Hp

[url=http://www.youtube.com/watch?v=2KUeO_4cPyw]www.youtube.com/watch?v=2KUeO_4cPyw

[url=http://www.youtube.com/watch?v=wBjxq6veeQI]www.youtube.com/watch?v=wBjxq6veeQI

Walk around the D26E6 Race engine. Next up wire loom and exhaust system and this one will be special.

[url=http://www.youtube.com/watch?v=r5Sk3HrWYCA]www.youtube.com/watch?v=r5Sk3HrWYCA

As some of you know most A class truck race engines are still on a lease of rental base and developed by the factory. I build A class truck race engines as well and I try to build them where possible with the factory parts as standard as possible. Fact is most of my customers are involved with road transport having a workshop some even run the same brand as there race engine so they can fix things in house or on the track if needed. Lest say they have the skills to work on these engines and maybe part of the fun of truck racing working as a team toward a race event.

On the A class Race engines the only things that’s needs to be rented is the ECU system. But you can bay an engine and use what your own ECU system to run it if wanted or run it on a B version ECU that are for sale but have a simple control strategy with less options and controls.

In general the engine gives the basic things to make power. The ECU system makes it possible the get the potential power delivery in a controlled way not damaging the engines and giving the drives the power or torque delivery needed for the track conditions. Customising the ECU to the truck and driver is one thing I do.

Yesterday in completed the dual running mode for FIA related races where they have to run in inlet restrictor to limit engine power and lets call it UK and NL races where there are no restrictions that limit engine power. As you can understand one engine set-up will not be ideal and that goes for the ECU system as well.

What makes a diesel engine work well? Well loads of air and a big bang is what we want. What is needed is a good combustion chamber and good fuel system and a fuel injector that dos deliver hi volume/quality fuel spay with a decent amount of stability.

I really like big stock injectors and yes some engines have them and we use them as well.

On some engines we have to make changes to the injector to get the fuel volume needed for these massive torque numbers coming out of the race engines. Lets say we go 40% more fuel flow over stock on the nozzle calibrated and all. Put this 40% over nozzle on a injector and you get more than 3% more fuel than calculated on hi load setting so why is this? I call this proportional imbalance. The fuel injector is not build to carry this amount of fuel to the nozzle so a bigger pressure drop under the needle in the tip of the nozzle moves the needle slower restricting fuel flow @ low coil on or opening time demanded by the ECU. So yes you get slower start of injection volume and it could be less accurate as well if not taking into account that more things need to be done. So looking @ a injector flow map fuel delivery will be less than stock @ low injector opening time. @ some point fuel delivery will be same as stock injector and @ some point fuel delivery will go massive above stock fuel injector due to slower closing time of the needle due to imbalance of pressure drop in the injector as it’s not build to handle the fuel flow.

Can we fix this problem with proportional imbalance due to pressure drop? Changing the valve assembly on a injector nearly impossible and to expensive/time consuming.

Proportional imbalance is OK on a injector as long as they are the same on all injectors. I know how to do this and get them to flow within factory offset specifications but this on it self is only half the things that needs to be done. The fuel delivery to the injector have to be balanced as well and that’s a game of correct orifices and fuelpump control.

Another day in my office working on diesel engines.

CNC machining the cylinder head. Minor changes are needed making a big difference. We have plenty of airflow on these heads and cam profile are very mild as it’s all based on massive low end power.

For older race engine we also produce these low CR pistons. They are cast and it’s actually better to move over to the forced alloy pistons used on the CR version of the diesel engine and chance the connecting rod in the process as well as the small end on these pistons is bigger as well able to handle more load and less chance of thermal cracks as well so they last longer.

For the A class race engines I’m now looking into on how can we improve the power delivery. The majority of these engines are run by multiple champions having the ability to make set-up changes while racing. The ECU I programmed has smoke and torque settings ideal for wet and dry and overtaking conditions but on some corners you want massive torque response while on others you want to apply the breaks and some engine power as well to stabilize a 5200Kg race truck and want a more gentle power response when the racetrack dos not provide a lot of traction.

Some very interesting information around these engines and racing classes. Such a good read. Thanks

A day in my office testing engines.

[url=http://www.youtube.com/watch?v=sRrrDqqS-lw]www.youtube.com/watch?v=sRrrDqqS-lw

New day in the office John Deere 404HTRT80C load testing

Wire loom ready for the D26E6A+ Race engine. Minor changes to the loom are boost solenoid and exhaust pressure sensor. Next up cabin wire loom and ECU system. All that’s needed is a 24V power feed to run our race engines.

Something you did maybe did not know about. The Asymmetrical Twin Scroll Turbocharger.

Definitely a good watch. Can certainly see the appeal of turbo diesel performance.

Diesel fuel. What about it? Well as some of you know we build engines for FIA European truck racing and as for this year we have to run on HVO fuel only so what are the differences and consequences?

Ok lest start with the basics. Normal diesel fuel as a density of about 841,8 Kg/m3,15g HVO has 780,8 Kg/m3,15g.

Now only the fun part. What energy dos it carry? Normal diesel has about 42,86 MJ/kg and HVO has 43,45 MJ/kg so that more energy so that always better? Well your not injecting MJ/kg but MJ/litter so as HVO has less Weight you need more fuel for the same Weight so where do we end up with?

Normal diesel has about 36,08 MJ/litter and HVO 33,91 MJ/litter so now we are down more than 6% on power running HVO injecting the same fuel quantity.

So 6% down on power. Easy fix you think. Well yes on some engines we build we can @ 6% more fuel but on most engines the fuelpump runs on 95% capacity also to reduce power take off losses. Simple a bigger pump needs more power from the engine to run.

Now something you never read about on diesel fuel. Diesel can be compressed more than you think. 15% for normal diesel @ 2000Bar is normal due to impurity of diesel. So if you compress normal diesel @ 841,8 Kg/m3 with 15% you get 968,07 Kg/m3.

HVO and even GTL diesel fuel is more pure so it will compress less so estimation is in total we will lose 2% engine power running HVO running the same Lambda numbers on a modern last generation diesel engine as these are build to burn old fashion crappy diesel fuel with a lower cetane number. So how come? Well hi quality of injection makes smaller diesel droplets easier and faster cleaner combustion. Also if we run GTL we get more EGT temp on the exhaust indicating less engine efficiency as well so GTL or HVO dos not help with a hi cetane number that will improve faster easy combustion on older diesel engines.

So next question could be what will happen to combustion pressure running HVO it seems to burn faster? I expect that combustion pressure build up will not chance a lot as long as your not increasing fuel pressure to shorten duration on injection giving more energy per time frame and faster combustion pressure increase. If this is what you want better retard start of injection a bit depending on CR of your engine not to hurt your engine.

So we have to run HVO fuel on the race engines and we will get the data in on performance so maybe we can run lower lambda numbers maybe gaining some power even on low inlet manifold pressure. Also the game is on building some hi efficient CR fuel pump for max engine power and torque.

2e Engine back from the machine shop.

Last week testing for FIA Truck Race where as for this year we have to run a HVO diesel.

Not going into detail about this bio diesel but think we get a great performance level out of it with changing engine settings and still improvement possible with a fuel and turbo system upgrades on the D26E6B engine turning it into an A or even A+ spec engine.

Last day spend on the track focus was on getting the correct engine power setting for the track conditions brining the lap time down a lot more than expected mainly keeping traction getting faster corner exit time as a result.

For those who think you can not run Lambda one all the time I have news we run these race engine from 13.8AFR low RPM max toque till hi end between 14,5 and 15 AFR. It’s all about correct combustion chamber fuel system fuel pressure and timing. Why so lean? Well like the rest we have to run a 63mm inlet restrictor in front of the turbo compressor restricting air mass and power and we can not smoke so it’s all about the details getting to that point. You can call it good or bad but if it smokes it’s losing power so that’s making a fuel mass set-up les complicated still have to go over a ton of ECU and data log data to find improvement on performance.

Bases on fuel we now make 5300Nm and 808Kw x 1.36 for hp makes 1099hp and even op top end @ 2452Rpm we make 801Kw so this 63mm inlet restrictor in front of the turbo compressor dos do it’s work well.

[url=http://www.youtube.com/watch?v=Z9FIeqkBVZk]www.youtube.com/watch?v=Z9FIeqkBVZk

[url=http://www.youtube.com/watch?v=iKhyCdrsoXE]www.youtube.com/watch?v=iKhyCdrsoXE

[url=http://www.youtube.com/watch?v=cxZ8pSXl_oM]www.youtube.com/watch?v=cxZ8pSXl_oM

D26E6A+ Race engine ready and already on it’s way to it’s new owner.

This is what you get if you sell your DID1 CAT ECM to CAT people.

More later on.