Sale ends todayGet 30% off any course (excluding packages)

Ends in --- --- ---

Tossing up changing my hotside out and going with an internally gated EFR 8474 on a 2JZ, I have read mixed things, but from my understanding they can have issues with blowing open when there's excessive exhaust back pressure. My car has a 4 inch turbo back exhaust so should be no problem. I've also heard the turbosmart canister is a good upgrade for them.

Just wondering what real world experience people have had with the boost control capabilities of these over an EWG and if I could run into issues.

The term "Backpressure" in a turbo application refers to the pressure level between the cylinderhead and the turbo.

NOT to pressure behind the turbo.

Having said this, a four Inch pipe after the turbocharger has nothing to do, yields very little if any, reduction in backpressure prior to turbine wheel.

Depending on WG spring pressure, whether internal or external, can/will be pushed partially open at a point.

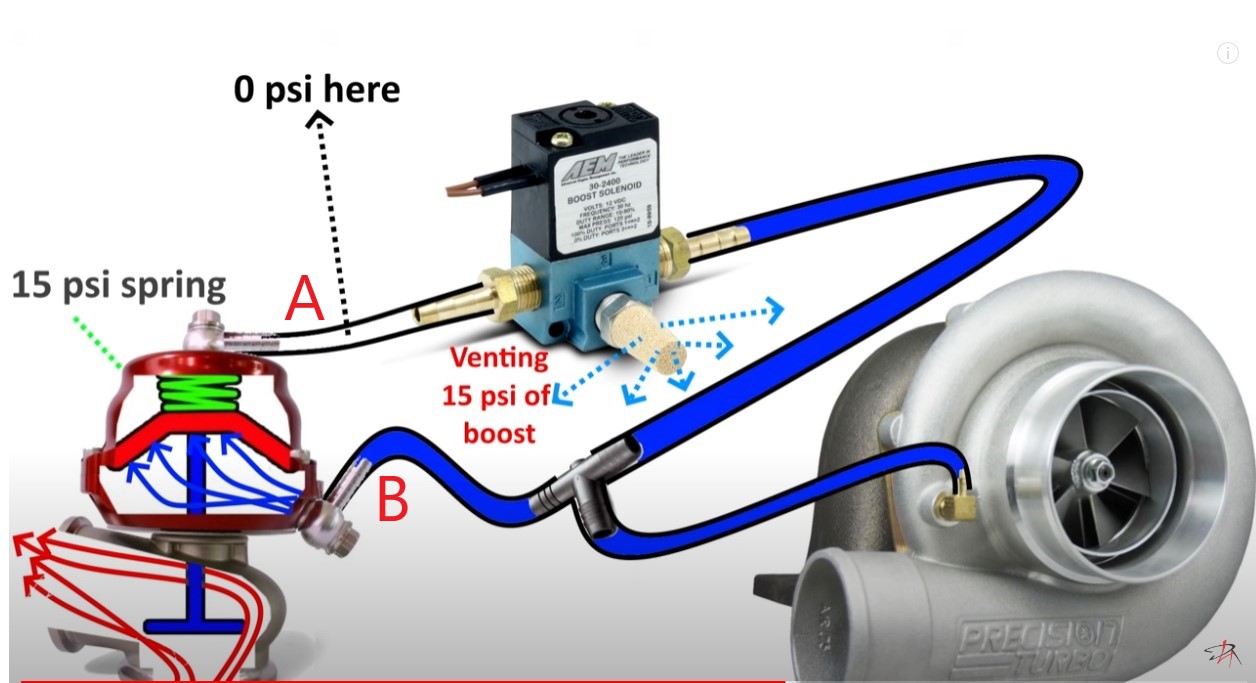

One way to counteract is the use a two port WG actuator, controlled via a three port valve and to apply boost pressure to the actuator (helping the spring keeping the valve closed) in order to minimize "push bleed" off during spooling up. Incorporating this method, steeper boost build up can be achieved as well as precicer control over boost altogether.

Two gate WG are usually of external type, I am uncertain whether or not internal actuators as two port versions exist.

FWIW

Putting a exhaust system that is less restrictive on an internaly gated turbine housing will usually result on higher boost level with the same boost controler DC. There is a maximum flow that the wastegate can achieve, if it can't bypass all the exhaust flow, boost creep will happen as the exhaust will be driving the turbine wheel. Porting the wastegate hole to prevent boost from going up to the moon is usually a good solution, when possible.

Dom,

Turbosmart makes two port wastegate actuators for internal WG's.

Thanks Stephen. Good info. I was not aware of that.

They're good, but they're a compromise as compared to a good EWG so it really depends on the system as a whole whether or not they'll be able to control it.

They're fantastic for packaging though.

Been researching this exact question on my 2J setup and wanted to get clarity. I am currently running an internal wastegate on a BW8 EFR 8474.

I upgraded waste gates to a two port turbo smart TS-0620-4012

Is this the correct way to plumb boost control?

OR....Should A and B get switched?

Hi,

That diagram will have the gate creeping a fair amount, as you only have the spring to hold the gate closed, and you are supplying boost to the open side of the diaphragm. It will quickly open, and close slowly.

With a Dual Port Waste gate, it is usually recommended to use either two 3 port valves, or a single 4 port. What you want is for the boost pressure to be added onto the top of the gate so that the pressure of the waste gate seat is Spring Pressure + Boost to hold the gate closed, and then bleed the pressure ouf of the top and feed it into the bottom to get a quick response from the gate when it needs to control the boost pressure.

Thanks for the response....do you have any diagrams of this?

also did you see that my waste gate is designed to run an INTERNAL valve? Just wanted to make sure that didn't change any of the routing options

From the Turbosmart website.

BlackRex,

Thanks for taking the time with this to help out. So that is the way I currently have it plumbed which is just swapping the A/B setup from the first pic that I posted. This method isn't providing the desired result for me.

Here is what I am after: I would like to hit 20 ish PSI on waste gate...and then have the ability to push up to low 30's which will be about the speed limit of this turbo. I have tried a ton of different spring combos and so far it either over boosts with waste gate...or I get lower psi with not enough top end and terrible boost fade up top.

I am considering trying this 4 port setup:

I have also been looking at this electronic waste gate solution and talking to full race to see if it will fit.

https://www.full-race.com/full-race-borgwarner-b2-efr-electronic-wastegate-conversion-kit

Open to suggestions on any of this....It just doesn't seem like it should be this hard to control boost in that type of range.

Thanks again for your help / insights with this!

-Saxon

That is the layout of how my turbo is plumbed, with the pressure from the post turbo manifold being applied through the IN port to the bottom of the gate (internal gate) to push it closed against the seat and the top port being open to atmosphere through the EX port. When the ECU is trying to control boost, the bottom port is switched from the IN port to the EX port, and the top port has the pressure from the In port applied to it. In these circumstances, I have found that using a lighter spring in the gate provides better control, as you only need enough spring seat pressure to hold the gate closed whilst the inlet system is pressurising (an EMAP sensor is useful in setting this up). Once the inlet manifold has enough pressure, as long as this pressure + spring pressure is greater than the EMAP then the gate will remain seated.

A lighter spring will also allow the boost control system to respond faster as it doesn't have to over come the spring before it can get the gate to move, although the exhaust pressure will also assist here.

BlackRex,

I ended up getting the system working today...thanks again for all of your help with this!

Also, as a side note and additional info for anyone else that ends up down this path I ended up speaking with TurboSmart and the waste gate design seems odd to me with this setup. When you look at their waste gate to control an internal system (like mine) the bottom port that you are supplying pressure to isn't fully sealed. The top is sealed from the diaphragm but the bottom isn't...at least not well. With a handpump I couldn't get it to hold any pressure and their tech said that was normal and that it wasn't designed to seal around the shaft that drove the actuator. So not all of the additional pressure being added is staying in that lower chamber....seems odd to me.

Regardless...finished up the dyno session today and the car made the power I wanted.

That's interesting, I have one of their 2 port internal gates and it holds pressure in the bottom chamber. Mine was a test/preproduction item though, so it may be that they have made changes to the design based on real world usage.

Hi Saxon how do you like the 8474 EFR? How early/fast does it spool in your 2JZ and is it a turbo you could use for the circuit that has a fair amount of slower speed corners? I'm curious as I also have a 3.0 liter (BMW 1M) so I should see similar results. I love the black series but this is the smallest EFR black series and to be honest I think it is one frame too large for my needs. If picking a G series turbo I would have gone G30-770 or G30-900. However, everything I read/hear about the EFR 8474 is that it spools really well and behaves like a turbo that is one frame smaller.