Dyno tuning isn’t easy — on your car, or your wallet. So when it comes time to finally get your car loaded onto the trailer and on its way to the dyno shop, why wouldn’t you want to be as prepared as you possibly can be? The very nature of dyno tuning — pushing your newly-built driveline to its limits — means that running into a problem, or quite often multiple problems, is to be expected. If luck is on your side, these issues could be quite minor and easily fixed on the day, but if not, you could equally end up wasting an entire day on the dyno with zero results, which, if you’re renting it by the hour, is going to hurt. On the other hand, if you’re running a tuning workshop, it can be challenging to charge out this lost time — either way, it’s something you want to do your best to avoid.

In this article, we’ll discuss common problems that surface during tuning and how to avoid them so you can make the most of your precious dyno time.

In this article: Fuel | Fuel system | Tyres and Locknuts | Spark Plugs | Clutch | Fluid Levels and Leaks | Boost Control | Base Ignition Timing | Charging system | Leak Down, Compression Test | Oil analysis

Fuel

This may seem very basic, but you’d be surprised how often people drop off their cars to be tuned and upon putting it on the dyno and starting it up, the tuner finds that the fuel light is already on. As we like to say, tuning is not magic — you’re going to need fuel and if you are completing a tune right from scratch, you’re going to burn through a pretty significant amount.

Along with the amount of fuel, it’s also important to have the car filled with the type of fuel that you are planning on running, which again, should go without saying, but some people either don’t even think about this, or they think that the workshop will be able to supply it, and that isn’t always the case. We’ve often seen cars delivered for tuning with high octane fuel, say 98 RON, when the owner intends to run it on a lower grade fuel such as 95 RON with the idea that they will get higher numbers on the dyno. It might net a few extra kilowatts, sure, but this doesn’t make any sense if there’s no intention to actually run the car on that fuel. There’s a real risk of the motor suffering from knock in this situation once it’s off the dyno and back on low octane fuel, and who do you think the customer is going to blame when a piston is destroyed as a result?

Fuel System

Another issue we’ve seen time and time again is a fuel system that can’t keep up. You need to make sure that both the fuel pump and injectors are sized correctly in order for them to keep up with the power levels that you’ve got in mind. If the fuel system isn’t big enough, this likely won’t be noticeable until quite far through the tuning process at high power/RPM levels, meaning it’ll be a couple of hours worth of dyno time before you figure out you’ve just wasted your day.

Sometimes, even if your fuel system should be up to the task, there can be a voltage supply problem to your fuel pump, meaning its maximum flow will be reduced. This is a little less obvious to diagnose but can be confirmed using a digital voltmeter connected to the terminals on the fuel pump.

Tyres and Locknuts

Exactly which aspects of this next issue you need to worry about will depend upon what type of dyno is being used. If it’s a hub dyno, the wheels need to be removed which, if the car has a set of lock nuts fitted, will require the lock nut key to do so. You’d be surprised by the number of people who have no idea where their lock nut key is, which makes it nigh on impossible to remove the wheels without wasting precious booking time destroying wheel nuts.

If your car is to be tuned on a rolling road dyno, you need to consider the condition of your tyres. There’s no need to have brand new tyres, but if they are worn with canvas visible, you risk having them fail, which will not only damage the dyno but also your car and rims. When checking tyre condition, especially if you are running a large amount of negative camber, it’s important to make sure you check the inside edge as this is where the majority of the wear will occur.

Spark Plugs

Ignition misfires are a very common issue whilst tuning, and there are a raft of reasons for it but the easiest to check is the condition of your spark plugs. If they’re old or worn, your engine may idle and run OK, but when you go to full load, it could cause a misfire. This again will waste time while you diagnose the problem and then remove and replace the spark plugs (if you’ve got a spare set handy, that is).

Equally as important as the condition of your spark plugs is the spark plug gap — you need to make sure it’s set correctly for your aims. The gap recommended by OE manufacturers is often not suitable for high boost applications and much like a worn spark plug, an incorrect gap will allow your engine to idle and run but when pushed to high load, will cause a misfire.

Clutch

The condition of your clutch is another important aspect of pre-dyno checks, and you need to make sure it’s up to the task. At the very least, make sure it’s not slipping — if it can’t take a full-throttle on the road, it will slip when under high load on the dyno.

Fluid Levels and Leaks

While you don’t need to do a full service on your car prior to putting it on the dyno, it’s important to make sure that you have checked the oil and water levels, as well as making sure you don’t have any leaks. For a workshop, leaks can make an absolute mess of the dyno bay, and as a customer, you may find yourself being charged a cleanup fee for this. Aside from making a mess, an oil leak could be dangerous if it makes its way onto a hot exhaust system as it has the potential to cause a fire, especially if the exhaust is wrapped with a fabric heat shield.

Boost Control System

If your car is turbocharged, it’s essential to make sure that your boost controller has been plumbed up correctly. Although these systems come with specific instructions which show you how to do this, it’s surprisingly common to have a car show up for a tune and when the car is put on the dyno, it becomes evident that the boost control solenoid or wastegate has been incorrectly plumbed, causing either excessive boost pressure or just no control over it whatsoever. This can cause serious engine damage as instead of slowly building the load as the tune progresses, you might end up shooting straight to high boost. Make sure the instructions that came with your system have been followed to the letter prior to getting your car on the dyno.

Base Ignition Timing

It’s important to make sure that the ignition timing you see on your laptop is the same as what you’re actually getting if you connect a timing light to the engine and look at the crank pulley. While this process should always be done by the person performing your tune, a common issue we see is for a car to turn up for a tune with no timing marks on the crank pulley, which wastes time since a positive stop will now have to be fitted to the engine to enable timing marks to be added. Make sure your car has timing marks prior to getting your car on the dyno.

Charging System

If your car has had an engine swap or an aftermarket standalone ECU installed to an engine where the alternator is controlled by the ECU, it’s possible that the engine may start and run but the alternator won’t work. Your car will be fitted with a 12 volt battery, but when the engine is running, the alternator will have the electrical system operating at about 13.8 to 14.2 volts. If the alternator isn’t charging, the car will run but your battery, if it’s well charged and in good condition, will start with perhaps 11 to 12 volts, and as the car is run and the battery is drained, the voltage will drop away. Before your car goes on the dyno, it’s important to check your battery voltage and make sure it increases after starting your engine. With some race engines that have an underdrive pulley on the front of the crankshaft or a special alternator, you may find that your alternator won’t start charging at idle and you will have to increase your RPM to around 3000 to make the alternator begin charging.

Leak Down and Compression Test

Although not a necessity, as a workshop owner, these tests give you the chance to pick up problems with the engine before you begin to tune it. This will avoid having your customer point the finger and try to blame you for any issues that were there from the outset. As the owner of the car, these tests can be a good idea to give you confidence that the engine is in good condition and if you keep a log of your tests, you can see whether there is any decline in your engine’s health over time. When doing this, it’s important to make sure you are undertaking these tests in the same conditions each time, as you’ll get different results when the engine is stone cold compared to under operating conditions. A leak down test can also help you better pinpoint where a problem is originating, as you can listen to the engine components to see exactly where the leak is occurring.

A compression test is useful for confirming that your compression is consistent across all cylinders but the actual numbers aren’t overly useful, because things like your cam profile and cranking speed will have an effect on the numbers you get. For example, readings of 120 and 180 psi could both come from a healthy engine, what is more important is that your readings for each cylinder are within a few percent of each other.

Oil Analysis

Much like a leak down and compression test, oil analysis is not a necessity but is a good idea, particularly for a highly-stressed engine, as you will be able to pick up whether you have a problem with an engine bearing before it gets to the point of failure, for example. This will allow you to save the expense of disassembling your engine to check your bearings, not to mention the time involved. All this test involves is using something called a wear check kit to take an oil sample and note down details of your oil and the engine which is then sent off for analysis.

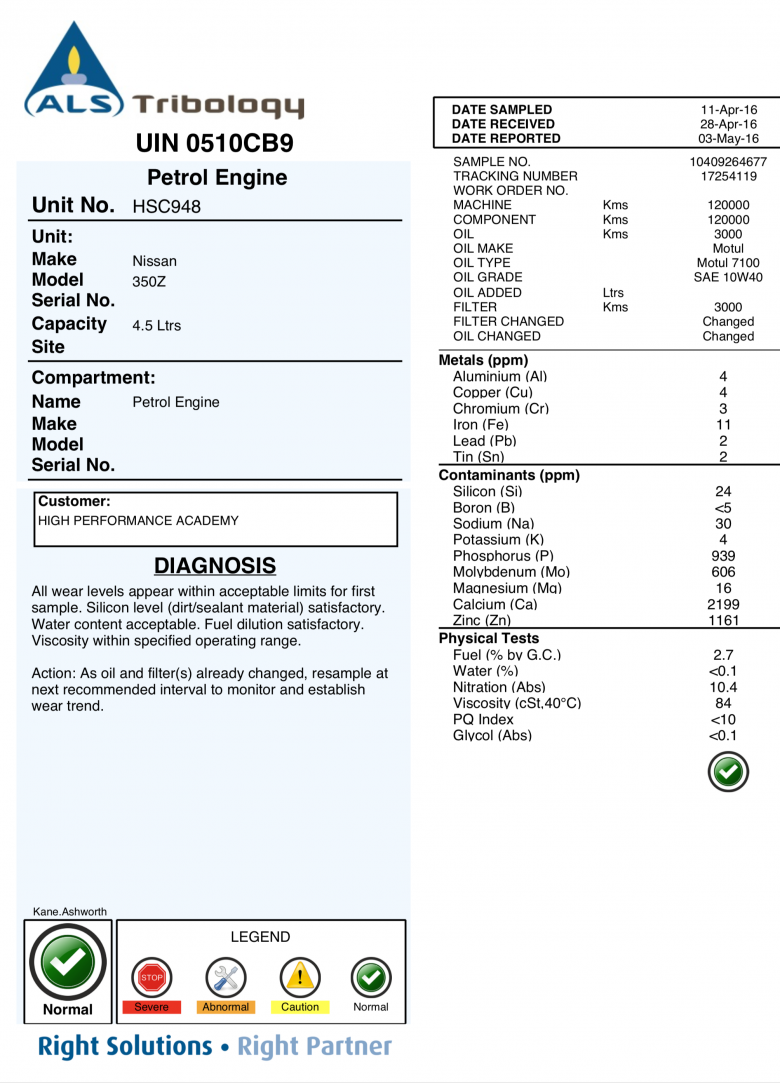

Shown above are the kind of results you can expect to receive from an oil analysis. This will include a diagnosis which summarises the findings of the sample and points out any abnormalities, or in this case, confirms that everything is normal and you’re good to go! Then on the right-hand side, you can see details of all the components of the oil, in particular, the metals section, which is where you’ll see signs of a bearing failure.

Conclusion

As you can see, none of the aspects discussed are overly difficult or time consuming to check but if done right, can save you, as the vehicle owner, a lot of time and money. If you own a workshop, on the other hand, it can save you that awkward conversation between you and your customers of having to charge extra for the wasted time. It might even be a good idea to use this as a checklist to give to your customers before they bring their car in for a tune. That way, even if you still come across issues, at least you can say “I told you so”.

Want to learn how to EFI tune? Start with some free lessons right here.