Composites might seem like the secret language of aerospace engineers and hypercar builders, but Gabriel Mountjoy from Common Fibers is here to break down those barriers. He’s out to prove that composites aren’t just exotic materials—you can use them to elevate your own builds too.

Listen on SpotifyListen on Apple Podcast

👉 Use the code ‘PODCAST500’ to get $500 OFF HPA's VIP Package: https://hpcdmy.co/podvip

In this episode of Tuned In, Gabe shares his journey from a mechanical engineering student passionate about automotive efficiency to a successful entrepreneur in the composites industry. Alongside his now-wife Ann, he co-invented the first carbon fiber hinge, and today their company is not only one of America’s leading composite manufacturers but also uniquely committed to educating people on how to work with these materials.

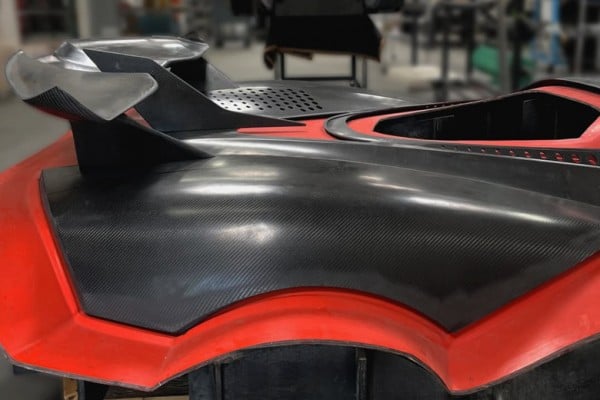

We explore the evolution of composites in automotive applications, the challenges and opportunities they bring, and why designing for manufacturability is key. Gabe also takes us inside high-profile projects like SSC North America’s Tuatara—a hypercar capable of 300 mph—explaining how they construct mission-critical, complex components such as its carbon-fiber monocoque.

Gabe breaks down the essentials of material and resin selection, unpacks layup methods, and clarifies the differences between wet layup, vacuum bagging, and resin infusion. He highlights the advantages of prepreg materials and compares autoclave with out-of-autoclave approaches.

Despite producing some of the most intricate composite parts in the U.S., Gabe and his team remain refreshingly open about their processes and deeply passionate about making composites more accessible.

Follow Gabe here:

Instagram: Commonfibers

Facebook: Common Fibers

YouTube: Common Fibers

WWW: commonfibers.com

👉 Use the code ‘PODCAST500’ to get $500 OFF HPA's VIP Package: https://hpcdmy.co/podvip

Timestamps:

0:00 From Home Builds to Hypercars: Composites for Everyone

4:37 Did the passion for cars come first or carbon fiber?

7:54 How do you become a composites engineer?

10:01 What’s your work history prior to starting Common Fibers?

11:18 Are composites much more common in other industries?

14:55 What does Common Fiber’s look like today?

16:11 How are you finding composite technicians?

18:06 Why did you open a second facility?

19:01 Can you briefly explain the different resin types?

21:30 What has been the process of growing a business to have 40 staff?

26:33 How much work are you doing for the aerospace industry?

29:22 What is the SSC North America Tuatara?

30:38 How did you get involved in the hyper car project?

32:30 How does the design and production work with the Tutara parts?

38:01 What’s the benefits of the monocoque over a conventional chassis?

44:11 When we talk about composites, what are the different materials?

47:23 What are the different types of carbon fibre?

49:18 What is carbon's best strength quality?

51:56 How do you validate the strength of your parts?

57:28 What is the process of designing and manufacturing a mold?

1:06:13 How do we layup the carbon or fiber glass into our mold?

1:14:47 What is a wet layup and where would we use it?

1:18:25 What is vacuum bagging?

1:23:02 What is resin infusion?

1:28:43 What is prepreg?

1:38:25 Final 3 questions

![146: From Home Builds to Hypercars: Composites for Everyone [PODCAST] - Featured Image](/assets/Uploads/blog-posts/300d94e62e/16-x-9-cover-thumbnails0__FillWzc4MCw0MzBd.jpg)

Comments

- LmMqtzme Åland Islands

3 months ago

- LmMqtzme Åland Islands

3 months ago

- LmMqtzme Åland Islands

3 months ago

- LmMqtzme Åland Islands

3 months ago

- LmMqtzme Åland Islands

3 months ago

- LmMqtzme Åland Islands

3 months ago

- LmMqtzme Åland Islands

3 months ago

- LmMqtzme Åland Islands

3 months ago

- LmMqtzme Åland Islands

3 months ago

- LmMqtzme Åland Islands

3 months ago

- LmMqtzme Åland Islands

3 months ago

- LmMqtzme Åland Islands

3 months ago

No one has commented on this page yet.