The most common, accessible, and arguably most useful form of 3D printing for automotive and motorsport work is Fused Deposition Moulding, or FDM. But what actually is it?

In this article: What Is FDM 3D Printing? | How FDM Printers Work | Kinematics and Machine Design | Printer Performance and Key Metrics | Material Capability and Temperature Requirements | Summary

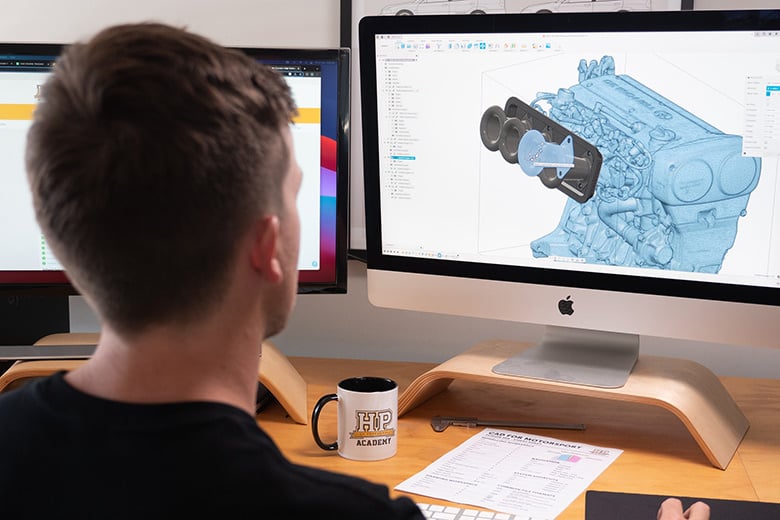

What Is FDM 3D Printing?

FDM works by melting and depositing thermoplastic material layer by layer to build a 3D object. This method is often also referred to as Fused Filament Fabrication, or FFF, and the technologies do vary slightly printer to printer due to patents.

The materials used in FDM are thermoplastic polymers, meaning they can be melted and reformed, and you will already come across the same class of plastics in everyday products like packaging (bottles & food containers), plumbing pipes, and our automotive interior trims. These come most commonly in filament form on spools, although pellets are sometimes used in large-scale industrial machines. While FDM is almost always associated with plastics, metals can technically be used in this process, although true metal additive manufacturing is usually performed with selective laser melting, or SLM.

How Do FDM 3D Printers Work?

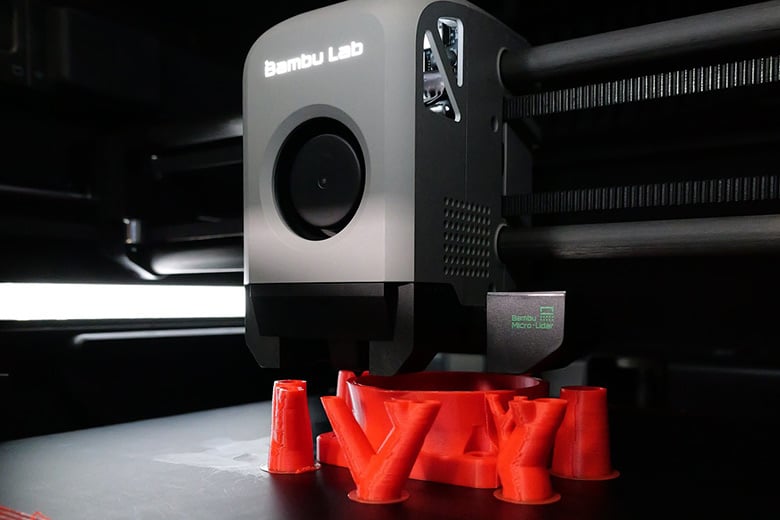

An FDM printer consists of three key components: the extruder, the nozzle, and the build plate. The extruder draws filament into the hot end assembly, where it's heated and pushed through the nozzle. This melted plastic is deposited onto the build plate, where it cools and cures with the help of a dedicated fan. As each layer adheres to the previous one, the model is formed gradually until the full part is complete.

The first layer bonds to the build plate, although not as strongly as layer-to-layer adhesion. Depending on the geometry of the part, support structures may be needed for overhangs or complex features, which can then be removed after printing.

3D Printer Kinematics and Machine Design

The motion of the printer is determined by its kinematics. Some machines move the print head in all three axes, while others move the head in the X and Y directions and move the build plate vertically to form the Z-axis. Many combinations exist across the market, each using slightly different mechanical arrangements to achieve the same outcome.

Other design variations include the frame construction, enclosure type, levelling mechanisms, and temperature control. Some printers even include enclosures with controlled environments to improve print quality. Regardless of the design, all FDM printers rely on CNC control, meaning they follow a programmed tool path to automate the manufacturing process, a lot like a CNC mill.

3D Printer Performance and Key Metrics

FDM printers range in price from hobbyist units under $1,000 USD to industrial machines costing hundreds of thousands. Here at HPA, we've used machines from a very basic Creality to more expensive but still 'affordable' printers like our current Bambu Lab X1E. Entry-level units are still capable but generally require more setup and attention, while higher-priced printers offer advanced materials, larger build volumes, and greater accuracy. It's also possible to outsource work to printing services to gain access to industrial machines when required.

There are a few key factors that influence the performance and price of a printer. Build quality, design, brand reputation, and customer support all play a part and can be difficult to quantify. Because technology develops so quickly, reviews and user experiences are often the best way to evaluate specific models.

Mechanically, the quality of the kinematics directly affects print precision. A stiff chassis, low compliance in joints and a lightweight hot end allow the machine to position the nozzle accurately and at higher speeds. This is similar to how reducing chassis flex and suspension compliance improves handling in a car.

Another core metric is build volume. Small consumer printers may offer around 150 mm³, while standard machines commonly offer volumes of around 250 mm³. Larger units can reach 400 mm³ or more, and industrial printers may exceed 900 mm³. If a part exceeds the available volume, we find that it's often possible to angle the print or split it into sections, depending on the geometry.

For example, our 250 mm³ is fine for prototyping and the parts we currently make, but if we wanted to do a lot more work creating bodywork moulds by joining 3D-printed sections, a 350 mm³ or 400 mm³ would be a better starting point. For occasional projects like that, though, a smaller printer will do the job, it just takes longer.

Speaking of time, print speed is another easily compared metric. Faster printers can reduce build times, provided quality is maintained, but print speed will still need to be adjusted based on the individual material requirements.

Printed Material Capability and Temperature Requirements

The materials a printer can handle depend largely on nozzle temperature. Different thermoplastics melt at different temperatures, typically between 150 and 350 degrees Celsius. Printers capable of higher temperatures can therefore print a wider range of materials. Heated chambers also help control cooling rates and improve dimensional accuracy and surface finish, especially with materials sensitive to temperature changes.

Some printers can even use multiple materials in a single build, either for different parts of the model or for support structures that are easier to remove. Advanced machines can also mix colours during printing, which can be useful depending on the type of work you're doing.

Fused Deposition Moulding Summary

FDM is the most accessible and widely used form of 3D printing and is a technology we take advantage of nearly every day at HPA. This accessibility makes it an ideal starting point for anyone entering additive manufacturing. The basic process involves feeding thermoplastic filament into a heated nozzle, which deposits material layer by layer to build a part. Printer performance depends on factors such as build quality, kinematics, build volume, print speed, and nozzle temperature.

Understanding your own requirements is essential. Features that matter in one application might not matter in another. With the right knowledge, you can choose a printer that fits your needs and produces reliable, accurate parts for your automotive projects.

If you'd like to learn everything there is to know about all types of 3D printing, check out the Practical 3D Printing course.