Holden and rotary engines have crossed paths before, but not like this...

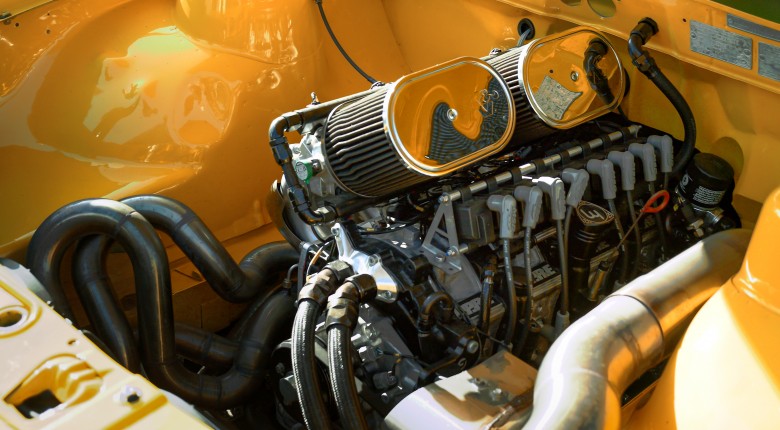

Fitting a 10,500 rpm 600hp peripheral ported 4 rotor into a Holden VL Commodore breaks more than a few cultural rules, and it does so in style.

Jay Duca from @lowstandards5269 Low Standards explains why he chose a quad rotor layout, the packaging and heat challenges that come with routing exhausts in a right-hand drive chassis, and how extreme (low) ride height decisions affect everything from exhaust tunnels to cooling airflow. The discussion dives into peripheral porting misconceptions, showing how modern electronic control units have transformed drivability compared to older rotary setups.

You also hear real-world reliability feedback from a PPRE four rotor that has survived high water temperatures, street driving, and multiple events with minimal servicing showing what a well built rotary can do.

Power output, rev limits, transmission selection, and why a Holinger RD6 six-speed was chosen are all covered, along with suspension and chassis modifications required to get a VL sitting just 30 mm off the ground.

--------------------

TIMESTAMPS

0:00 - Rotary Power In A VL Commodore

0:32 - Why A Four Rotor Swap Happened

0:55 - Quad Rotor Packaging Challenges

1:21 - Exhaust Routing And Heat Problems

2:10 - Ride Height And Fabrication Tradeoffs

2:18 - Peripheral Porting Drivability Reality

3:02 - ECU Control And Modern Rotary Tuning

3:18 - Choosing PPRE For A Four Rotor Build

4:27 - Rotary Reliability And Maintenance

5:13 - Power Output And Rev Limit

5:28 - Holinger RD6 Gearbox Selection

6:00 - How The Car Sits 30 mm Off The Ground

6:29 - Independent Rear Suspension Decisions

7:10 - Rotary Culture At Summernats

8:08 - Respecting Engineering Over Engine Type