MotoGP, WRC, F1, Formula E...these are just some of the motorsport disciplines that Renvale Ltd constructs wiring harnesses for. Let’s dive in and take a look at the process that goes into the design, manufacturing and testing of a professional motorsport wiring harness.

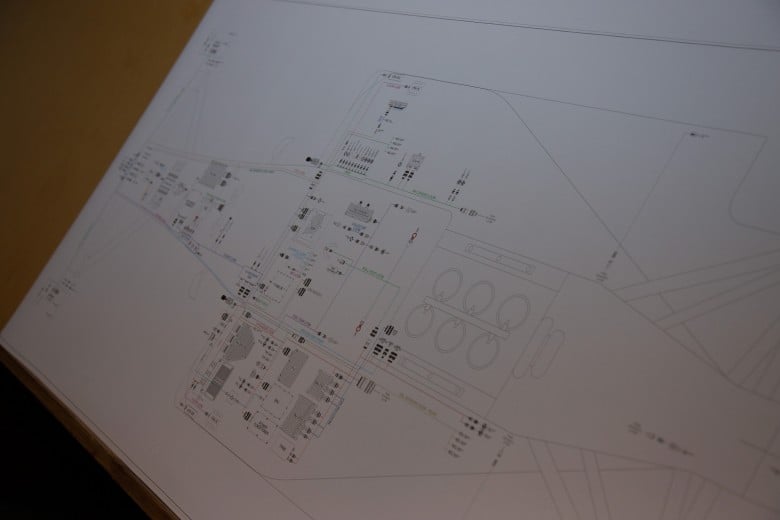

For the design aspect an engineer can travel to the vehicle to create a mock-up harness using cheaper components as a template to create the harness documentation from, and then the real deal, however it is more and more common, particularly in the world of Formula 1, for the teams themselves to supply 3d models of the vehicle to Renvale from which the design can be drafted, homologated by the FIA which also removed the ability to make any further changes once approved, and then later of course produced.

On the construction side of things there is usually a margin allowable for differences in length and width to what has been documented, but for F1 looms Renvale removes the margins and ensures the construction is exacting down to the mm. Even with minimal wiring experience, it’s easy to tell how difficult this can be. Interestingly for F1 looms concentric twisting is not used, and instead, Renvale opts for parallel twisting. This is due to the ability to support, protect and route the loom via carbon fibre guides which removes some flexibility requirements, and also simply some weight reduction as little to no filler wires are required.

With weight in mind, the gauges of wire used can range from 22 down to 30 AWG and rather than complicate stocks, construction and assembly white wire is used for the majority of the loom with coloured idents attached for assembly guidance. While this might sound like a nightmare for future serviceability, it is worth noting for this specific application that particular consideration is not a requirement. From there Raychem DR-25 and moulded boots are used to seal and add protection to the harness.

Even with exacting documentation and extreme diligence, testing is a critical and sometimes overlooked part of the construction process. At Renvale a Cirris hipot tester is used which tests every connector and also the integrity of the harness to ensure everything has been constructed correctly, nothing has been nicked or damaged, and also that everything is in the correct location. Although not applicable to these Formula 1 harnesses, if required, machines like this can also test for resistance and ensure your termination resistors for CAN communication wiring are correctly installed.

Want to learn how to create your own wiring harness? Start with a free live lesson.

![What Goes Into A MotoGP, Formula 1, WRC or Formula E Wiring Harness? [TECH TALK] - Featured Image](/assets/Uploads/blog-posts/c0372577be/Goodwood-3363__FillWzc4MCw0MzBd.jpg)

Comments

No one has commented on this page yet.