| 00:00 |

- One of the most important factors of our wiring harness power supply design is the size of the wires providing power to each component.

|

| 00:07 |

There is a lot of opportunity for error here.

|

| 00:10 |

The results of which can be pretty catastrophic.

|

| 00:12 |

So we need to be careful and logical in our approach.

|

| 00:15 |

We need to ensure that the wire we have supplying power to each device is capable of doing so without overheating as this can melt the insulation around the wire, leading to a fire.

|

| 00:25 |

We do this by looking at each powered component individually and working out the amount of current that it will draw.

|

| 00:31 |

As discussed in the electrical fundamentals section of the course, we can determine this using ohm's law or the power equation, depending on the information that we have access to.

|

| 00:40 |

Once we know the current the device is going to draw, we can determine the size of the wire we need to run to it.

|

| 00:46 |

It's typical to use the smallest size of wire that will safely handle the current level as this is cheaper and reduces both the bulk and the weight of the loom.

|

| 00:54 |

However like many things in the automotive world, the story is not quite that simple.

|

| 00:58 |

We also need to take into account of where we splice one power supply wire out to different electronic components.

|

| 01:04 |

If we look at the fuel injectors for example, we might run a single wire from the supply relay to a location close to our injectors where we then splice and branch it out to each individual injector.

|

| 01:16 |

In an instance like this, the section of wire before the splice is carrying the current of all the injectors so it will most likely need to be a larger size than the individual wires to each injector after the splice.

|

| 01:27 |

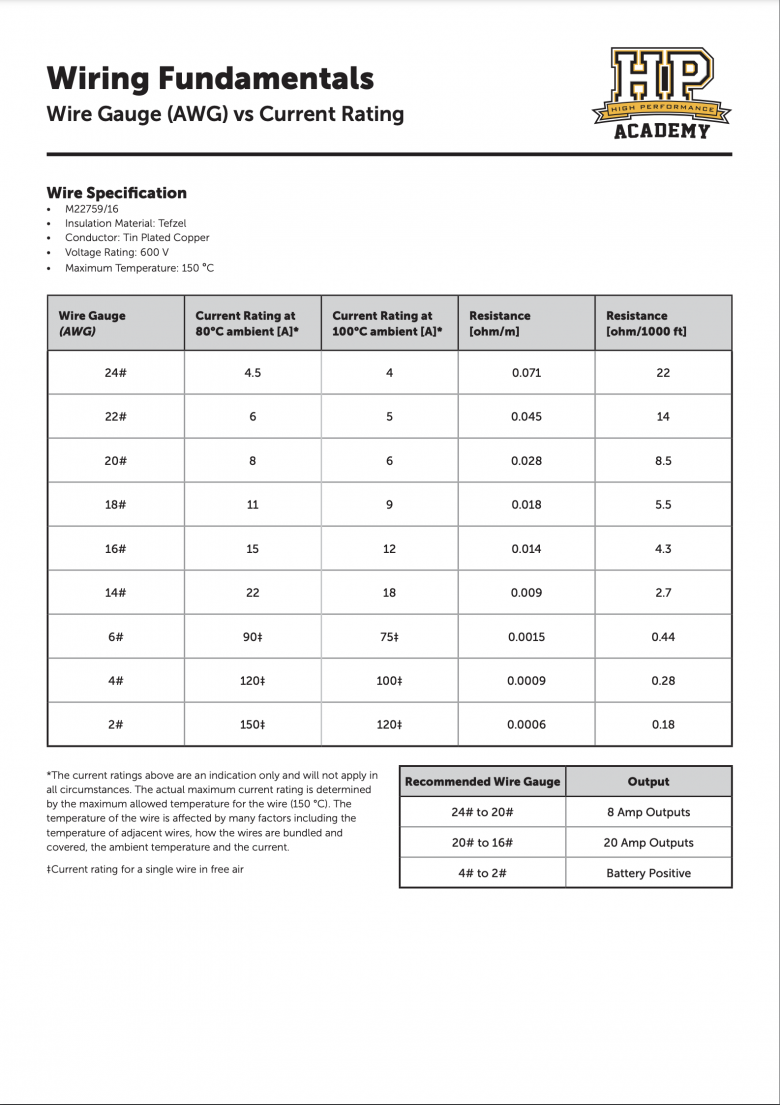

Attached below this module is a worksheet showing different wire sizes in American wire gauge and their current handling capability.

|

| 01:34 |

We've also included a cross over to the closest metric unit equivalent as although AWG is a more prevalent unit when you are purchasing wire, you're likely to strike the metric units, millimetres squared, sooner or later.

|

| 01:47 |

In particular, OEM documentation for Japanese vehicles will denote the size of the wires in metric units.

|

| 01:54 |

As a quick demonstration of how critical correct wire sizing is, we'll show you what happens when a wire is undersized.

|

| 02:01 |

We have a simple set up here, it's a switch controlling a relay which is supplying power to the load, two halogen headlight bulbs in this instance.

|

| 02:09 |

As the bulbs have a rated power consumption of 55 watts, and we're powering them from a common car battery, we know they will draw approximately four amps each, for a total current draw of eight amps.

|

| 02:21 |

We're supplying power to the bulbs here using a 22 AWG wire, which we have purposefully undersized.

|

| 02:27 |

You can see that when we turn the switch on, the copper wire quickly heats up and the insulation begins to melt and burn.

|

| 02:34 |

For this demonstration we have exaggerated the effect.

|

| 02:37 |

But even a marginally undersized wire which is bundled tightly in a wiring harness can cause damage.

|

| 02:43 |

If the wire is in the middle of the harness it can't radiate any of its heat away directly to the atmosphere.

|

| 02:48 |

The entire harness may also be subject to external heat sources in the engine bay, further compounding the problem.

|

| 02:54 |

You can also imagine that if a wire in the middle of a harness overheats, the damage will not be limited to that single wire itself.

|

| 03:01 |

While it is essential to calculate the current draw of the EFI system components and ensure the wiring is sized adequately, for a modified street car wiring harness, using TXL wire, I do have some common rules of thumb to get things in the ballpark initially.

|

| 03:15 |

I supply power and ground connections to ignition coils using 18 AWG wire, and to injectors using 22 AWG wire.

|

| 03:24 |

Almost all sensors and switches are powered, grounded, and signal wires run using 22 AWG wire.

|

| 03:31 |

High current loads such as fuel pumps and cooling fans use 14 AWG wire.

|

| 03:36 |

These values all need to be double checked but they provide a good starting point.

|