Sale ends todayGet 30% off any course (excluding packages)

Ends in --- --- ---

I am trying to tweak a timing map but do not have access to a dyno for proper setting. The background: Engine is an aluminum block, aluminum head, Ford FE, 468 in., Borla EightStack injection using a Performance Electronics ECU. Car is running great. I am unable to determine any issues with knock. I think this is probably due to the combination of the aluminum structure which tends to sound deaden, the louder than normal exhaust system and the sewing machine noise of the valvetrain (Hydraulic roller w/ roller rockers)

Can anyone help me to understand or learn any tips as how to determine when too much timing has been added to a particular range? The ECU allows me to run a table based on MAP which I have set up to serve as a Vacuum Advance 0-14 degrees, depending on MAP. MAP at idle is approx 60kpa

This style engine seems to prefer about 38degrees centrifugal, all in at 2800rpm.

The ECU system runs in Alpha-N mode so comparing other timing tables on the load side to this one is difficult to do.

As I stated, the car is running fine, I am just trying to improve the efficiency. To give you a sample, cruising at a light load (65MPH, flat road, no accel): RPM-2184, MAP-76Kpa, Vac Adv-4.5*, Total Timing-32.7* My MAP is rarely getting below 60Kpa and it appears only when I let of the throttle to shift, at which time the VacAdv will jump to 12 but rarely do I see this much advance in the cruise ranges. My typical cruise range is 1900-2500 rpm and 3-8 TPS%

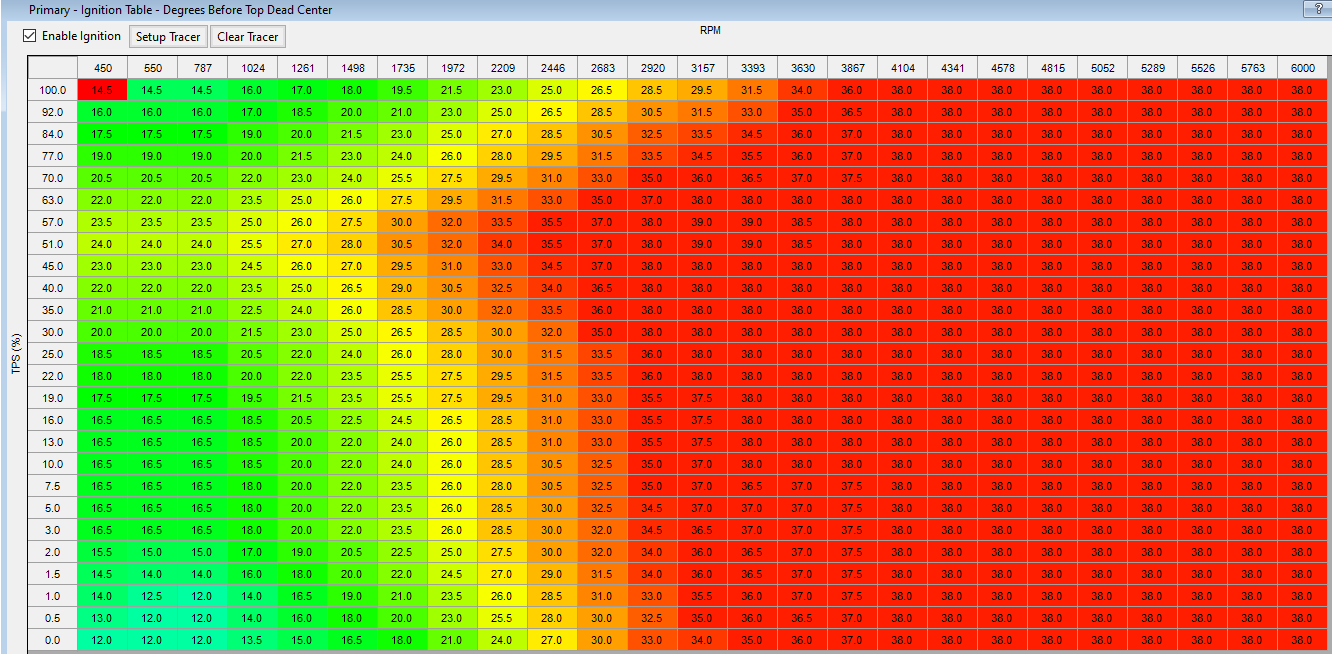

I hesitate the just start throwing a bunch of timing in, knowing the issues it can create. Open to any suggestions on the best method to tweak these settings. This is a picture of my timing map from the ECU

I've attached the file in case the image isn't clear enough.

Thanks for any help you can offer a newbie,

Paul

MAP does not work well with IR TBs, it really needs a plenum post 'a' TB - you'll find it much easier using throttle position and rpm only.

There shouldn't be any 'sewing machine' noise for correctly pre-loaded hydraulics - it's probably the injectors, got caught out like that myself with the first EFI engine I had, but realised just before I ordered a new set of followers.

Any luck finding the magazine article on the Shelby alloy FE I mentioned in another post?

Gord

I am running Alpha-N (RPM & TPS%) the manifold I have incorporates a vacuum chamber and my ECU is able to use that signal for user defined compensations - best of all worlds.

The Sewing Machine noise is the ramp on the cam, it seems to be inherent to the design and has been acknowledged by others and also by the manufacturer.

Yes, I did find the article. Thanks