Whether you're buying your very first TIG welder or upgrading an older machine, there has never been a better time to enter the market.

Modern welders are smaller, more powerful and far more adjustable than ever before, giving you the control needed to complete all types of automotive and motorsport fabrication jobs from your own garage.

With that adjustability comes an overwhelming number of options, so understanding what matters most will help you make the right choice the first time.

In this article: Why You Need a TIG Welder | Welder Power Supply and Amperage | Multi Process vs Dedicated TIG Welders | AC/DC Capability and TIG Torch Types | TIG Weldong Attachments and Accessories | TIG Welder Buyers Summary

Why You Need a TIG Welder

If you're here, it's safe to assume you are interested in motorsport fabrication and want the best TIG welder that your budget allows. Along with performance, we always look for good after-sales support, a wide range of compatible consumables, and the ability to weld extremely thin metals, while still having enough headroom for occasional thicker materials.

Most fabricators also prefer the ability to weld as many metals as possible, which is an important consideration that'll influence your final choice.

Power Supply and Amperage

The first step in choosing a TIG welder is understanding what power supply is available in your workshop. There's no point buying a machine you can't run, so start by checking your outlets and matching these to any welder you're considering.

Thanks to modern inverter technology, power consumption has reduced significantly, and many welders capable of automotive and motorsport work can run from a standard home outlet while still offering the performance required for a wide range of metals. This isn't universal, though, so make sure to check on the requirements of any machine you're interested in.

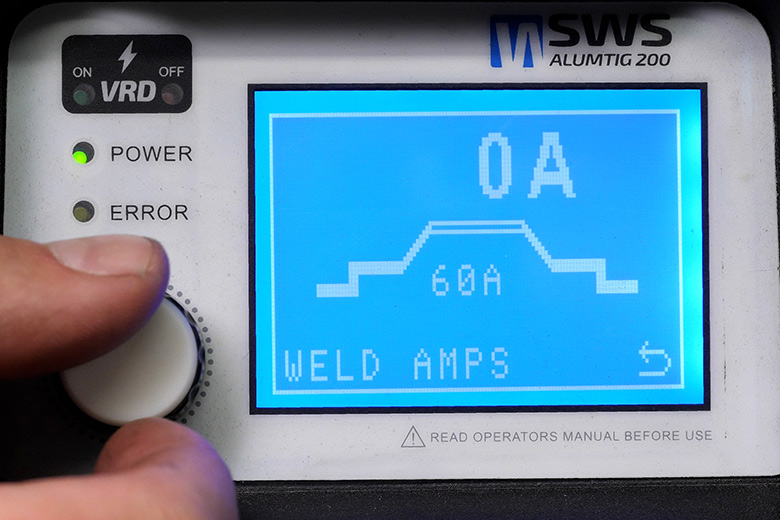

Welding heat is defined by amperage, which will be the first specification you notice, and a 200-amp welder covers the vast majority of motorsport fabrication work. Machines in this range can weld material as thin as half a millimetre and up to approximately 6 millimetres. Here at HPA, we use an SWS Alumtig 200, which, as the name suggests, is a 200-amp welder that does everything we need it to for nearly any automotive project.

Multi-Process vs Dedicated TIG Machines

Multi-process machines that combine MIG and TIG capabilities in one unit are quite common. Although this might seem ideal, these machines are rarely the best option for motorsport fabrication.

Switching between processes requires different inert gases and time-consuming setup changes. While a multi-process machine can be appealing, everything you can do with MIG can be done with better results on TIG, so unless you specifically require MIG capability, a dedicated TIG machine will offer fewer compromises and better performance for the money.

AC/DC Capability and Torch Types

TIG welders will be labelled as DC only or AC/DC. A DC only machine limits you to steels such as mild steel, stainless, chromoly, and titanium. An AC/DC machine adds the ability to weld aluminium, which is a major advantage in motorsport fabrication and what we use here at HPA.

Even if you have no plans to weld aluminium right away, upgrading to an AC/DC welder is worthwhile if your budget allows. As your projects grow, the extra capability will almost certainly pay off.

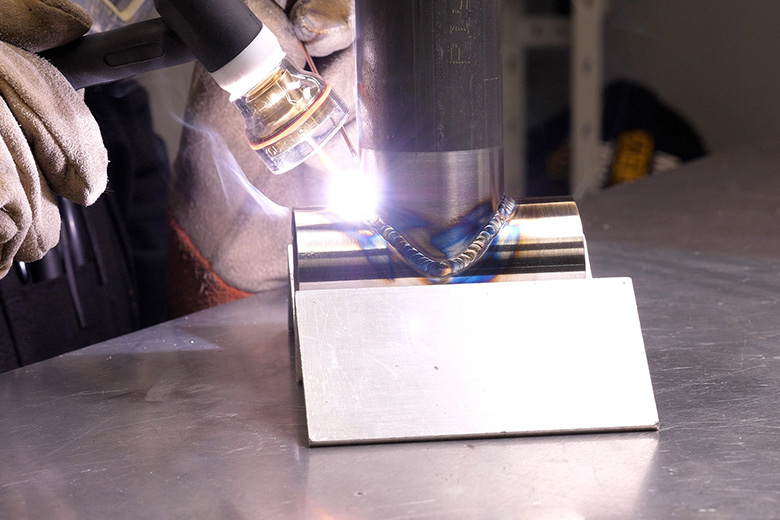

TIG torches are offered in air-cooled and water-cooled variants, and air-cooled torches are the most common option on motorsport-focused machines. They're smaller and perfectly suitable for most fabrication tasks, and it's what we use here at HPA.

If your projects involve long welds on thicker aluminium where heat builds quickly, a water-cooled torch may be a worthwhile addition because it dissipates heat more effectively and allows longer high-amperage welds.

Included Attachments and Accessories

When comparing different machines, take note of what's included in the package. In many cases, it is more cost-effective to buy a slightly more expensive machine that already includes a plug-in foot pedal, quality flex head torch, gas lens kit, and consumables.

Most welders are supplied with a gas regulator, an earth lead, and a TIG torch. You'll need to purchase an Argon bottle, tungsten electrodes, filler rods, and PPE such as a welding helmet and gloves.

Machines designed specifically for motorsport fabrication will usually mention this in their product description. These machines often include refined programming and settings that make intricate work easier.

Summary

There are many options available when choosing a TIG welder, but the decision becomes easier once you understand your goals and the type of work you plan to complete. A 200-amp TIG welder, like the SWS Alumtig 200 we use in our workshop, will cover most motorsport fabrication tasks. If your budget allows, an AC/DC capable machine is highly recommended for its versatility and the ability to weld aluminium.

Before you walk into a shop, be clear about what you want to achieve with your welder. This will help the salesperson point you to the most suitable machine and prevent frustration down the track as your skills improve. Package deals that include pedals, gas lenses, and torch upgrades often end up saving money in the long run, so consider them carefully before making your final choice.