Sale ends todayGet 30% off any course (excluding packages)

Ends in --- --- ---

We all know every shop manual says keep all re-used components in their original locations/orientations. I'm looking for advice on where the line lies that you have thoroughly examined the teardown enough to determine that parts can me mixed and matched. For example, maybe you want to swap parts around to avoid stacking tolerances or god forbid your tray of parts gets scattered somehow.

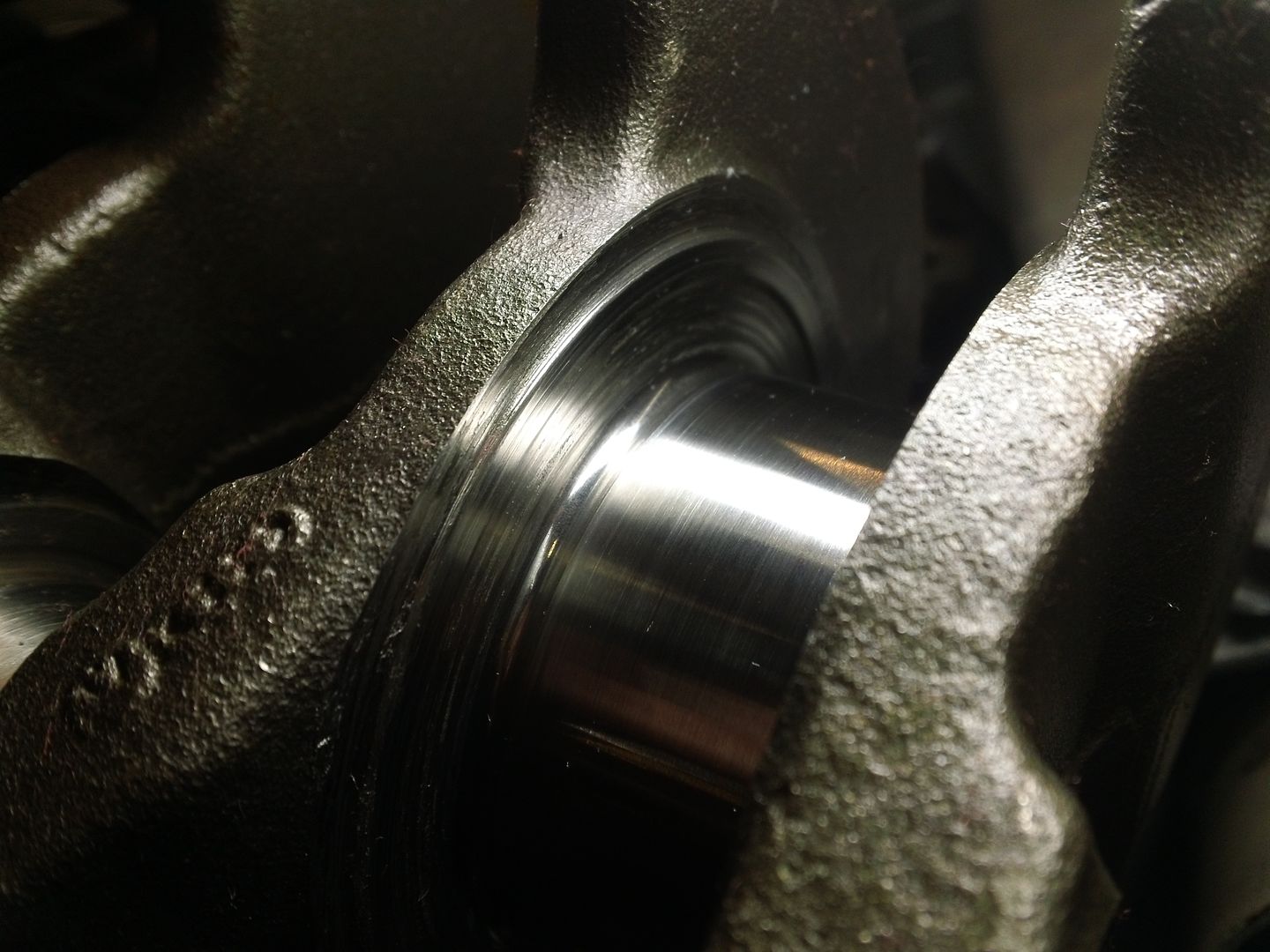

For context (ignore if it's irrelevant to the original question), the VW 16v engine I'm intially using to apply your engine building courses is to 30 years old, previously rebuilt (.5mm overbore), ran/drove on 3 cylinders when I removed it, is both damaged and worn out, and required a bent connecting rod and thrust-damaged crankshaft be replaced. My machinist found me a reman stock rod that visually matches the rest and I found a used crank in good condition that polished up great. I'm just getting underway with measurements, but keep wondering at what point do I know I can swap around used pistons/pins/rods if desired? I'm most curious about the 20mm full floating wrist pins, and if/how I can measure the bores in the pistons and rod bushings.

The headgasket leaked enough to hydrolock cylinder 2, and some previous owner preferred the clutch over letting it idle in neutral.

While it's best practice to keep components you're going to reuse in the same location, this isn't a rule that's set in stone. If I was to reuse a set of piston rings then these should definitely be kept in the same location in the block however if you're re-ringing the engine then it's not uncommon to swap the pistons around. What you will find with all of these components is that they tend to wear into location which is why we normally keep them in the same location. If there's no significant wear and your clearances and measurements stack up then you could move components if needed. My question would be what are you hoping to achieve by swapping a piston to a different cylinder or a conrod to a different piston though? I'm not sure I see any advantage as we don't balance the rod and piston together - All rods are balanced together and all pistons are balanced together.

Thanks for a great answer, Andre. I'm probably overthinking things as usual.

As I said, I'm just getting underway with measurements and acquiring some more specialized tools (and lack practical balancing/blueprinting experience). For example, I could conceivably find out that my piston to wall clearances are all ok, but swapping them around could get a better average fit. I certainly won't know what I might hope to achieve until I have a full set of documented measurements. Maybe this is just inexperience talking...

I've also found it impossible to get consistently repeatable big-end conrod weight measurements so far using a few cob-job solutions instead of a proper fixture. Your lessons are definitely right about the difficulty here, and hasty measurements (even with a fixture) could definitely result in removing material many times and chasing around my own inaccurate practices.