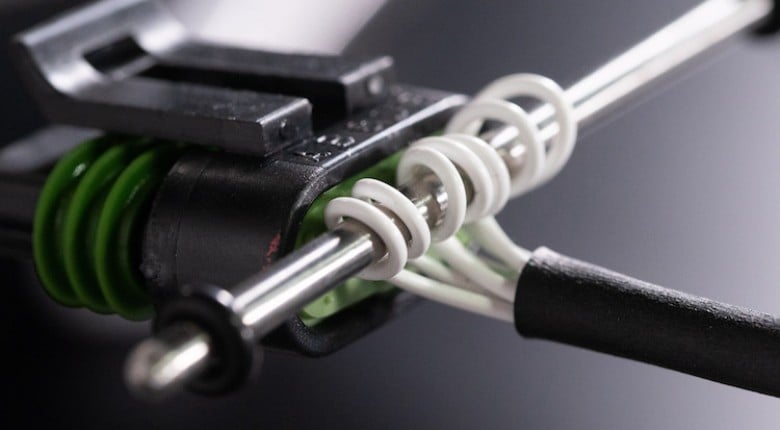

If you've ever admired a photo of a neatly wired Autosport connector and a harness with with concentric twists, chances are you’ve seen the unsung hero of motorsport wiring: the service loop. Often misunderstood or overlooked by those new to professional motorsport electronics, service loops are a critical part of a reliable, reconfigurable, and robust harness.

Let’s break down what service loops actually do, and how to make them look as good as they function.

In this article:

What are service loops and should you use them?

Service loops serve two core purposes in a custom wiring harness:

1. Future-Proofing for Reconfiguration

The most crucial function (and the reason they are called service loops) is flexibility for future updates.

No matter how much planning you do before creating a wiring loom, the reality is that vehicles evolve over time and there is always a possibility that wires will need to be moved in the future. In many cases, this might mean moving from a wire from a 5 volt feed on one side of a connector, to a 12 volt feed on the other side. If that change needs to happen, having the extra loop of wire will allow the pin to be moved across without stretching or joining the wire to reach the new location.

This capability is invaluable when changing pin layouts. Without a service loop, a reconfiguration might require building an entirely new harness section, or having to patch wires into your loom - it’s preferable to avoid both if you can.

2. Strain Relief

Service loops also help with strain relief - particularly when used with non-booted connectors like the Deutch connectors that are commonly used in custom wiring looms. A properly implemented service loop acts as a buffer zone and allows for some “spring” if someone tugs on the loom. In this case, the loop helps to distribute that strain away from the pins and other delicate parts inside your connector.

When service loops are combined with a moulded boot or connector back shell (often epoxied), any force is transferred from the loom, through the boot, and into the rigid housing of the connector, rather than through the wiring itself. In this scenario, your loop is a second line of defence to prevent damage to the wires, crimps, or connector pins.

How to Build Clean, Effective Service Loops

Creating tidy service loops isn’t easy, but it’s definitely achievable with practice. Here are some pro tips:

Always Have a Plan

Planning is everything. If you’ve put in the work to plan your pin-outs and harness shape, you will already know where each pin and wire is going. You can start by pinning the most densely populated connector - such as the ECU, PDM, bulkhead connector, or digital dash - and work your way outward from there.

90° Boots - Start From The Inside Bend

When working with 90-degree shrink boots, always start building your service loops from the bottom of the bend and work upward. If you begin in the middle or outer edges, you’ll quickly run into space limitations as you reach the bend.

Use Scaled Templates

Some suppliers will offer technical drawings of their shrink boots. You can print these out to scale and use them as a visual guide when laying out wires. This helps avoid a tangled mess and ensures everything fits before shrinking the boot.

Create Reusable Jigs

Heat and shrink a boot, then cut it in half on a bandsaw to create a reference jig. You can test your loop layout against it to make sure your wiring will fit before committing to the final build. These half-boots are great long-term tools to keep in your toolbox.

A Note on Instagram vs. Reality

Yes, beautifully arranged service loops make for great social media content, but remember that how your wiring functions is the most important part.

Once you wrap your harness and shrink everything down, those picture perfect loops will be hidden from view, and that's ok. The extra work it takes to create these loops is all about function, rather than form [moulded boots and raychem wiring harnesses do look hot, though 👌]. What matters is that they serve their purpose: serviceability and strain protection.

Final Thoughts:

Service loops are a crucial but often overlooked element in high-quality motorsport wiring. They serve two key functions: serviceability - allowing flexibility for future reconfiguration without rebuilding sections of the harness, and strain relief to protect connectors from mechanical stress. While making them look neat takes practice, thoughtful planning, correct looping technique and using templates or reference jigs can help.

Ultimately, service loops are about function over form: even if they’re hidden in the final install, their value lies in durability and long-term serviceability.

If you're ready to get hands-on with wiring your own project, check out the Practical Wiring - Professional Motorsport Course and take your wiring skills to the next level.